TPX 252

Your advantage:

- 1 colour

- highest precision and printing accuracy

- electropneumatical

- compact design

- sealed inking system

- lateral ink cup movement

The TPX 252 pad printing machine with sealed and lateral sliding inking system is driven electropneumatically.

Depending on the requested application, two different sized inking mechanism strokes are available. Based on the inking mechanism stroke, different ink cup and plate sizes can be chosen.

Highest precision and repeatability characterize the TPX 252 as a high-quality pad printing machine.

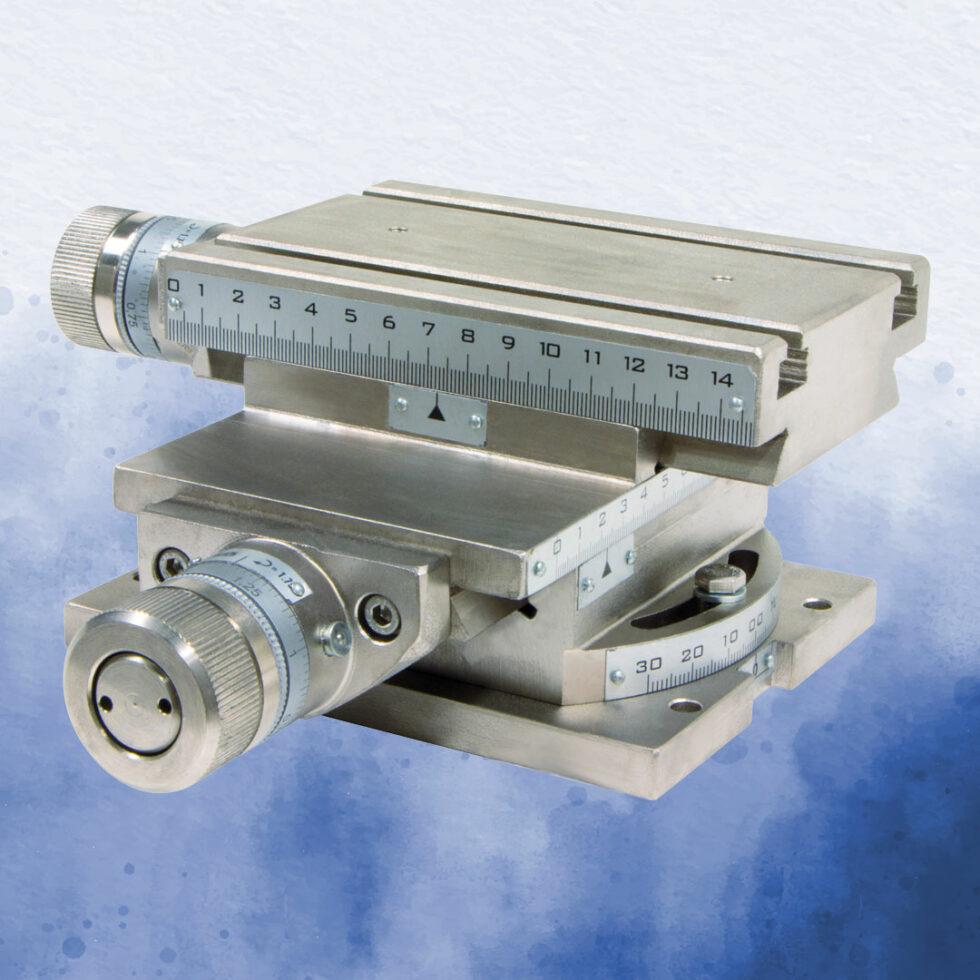

For the fixation of the ink cup, either the electrical, rotating cup cylinder or the cup holder with bayonet lock are available. Different accessories as e.g. machine base or coordinate table as well as further equipment like the automatic pad cleaning device or peripheral units are offered suitable for the TPX 252.

The TPX 252 pad printing machine can be equipped with a cup holder with bayonet lock or the rotating, electric cup cylindern.

Our team assembles the high-quality TPX 252 with ultimate care and passion.

The ink cup on the TPX 252 pad printing machine moves from left to right.

Technical data TPX 252

Number of colours:

1 colour

Stroke inking mechanism:

150 mm / 240 mm

Ink cup sizes:

Ø 72 / Ø 86 / Ø 96 / Ø 115 mm

Plate sizes:

standard plate widths: 100 / 120 mm

standard plate depths: 200 / 220 / 250 mm

Output:

up to 1’400 cycles per hour

Drive system:

electropneumatical

Repeat accuracy:

< ± 0.02

Printing force:

700 N (printing force has to be balanced)

Mains connection:

230 V / 50 Hz, 5 – 6 bar air pressure

Air consumption:

0,87 resp. 1,1 litres / cycle at 6 bar

Control:

PLC – HMI touchscreen

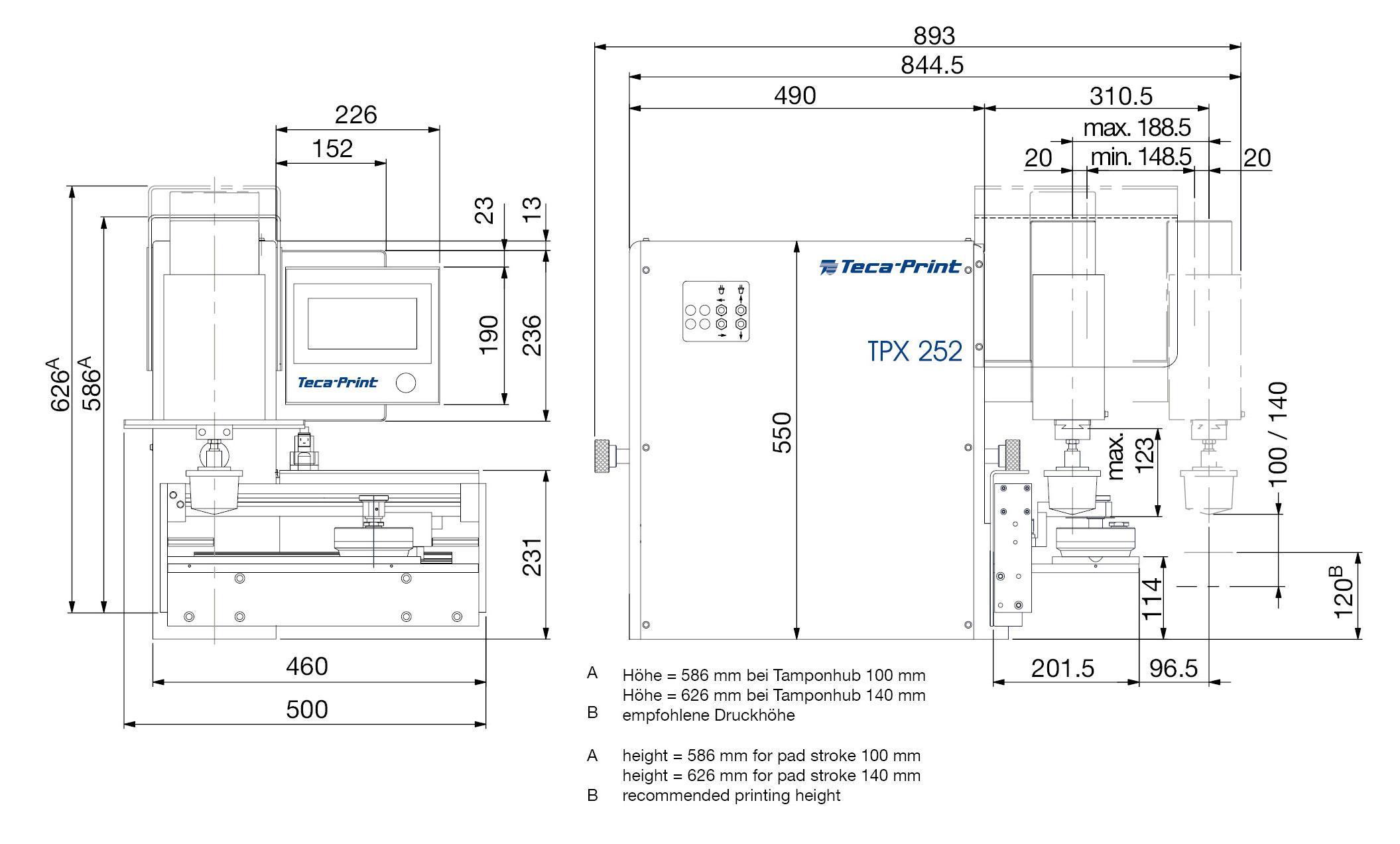

Vertical pad stroke:

100 / 140 mm, electronical infinitely adjustable

Outreach pad carriage:

96,5 mm

Weight:

approx. 83 kg without machine base

Dimensions (WxHxD):

500 x 586/626 x 892 mm

All specifications and options depend on the inking mechanism stroke and are partly defined by this. We will be happy to advise you in detail.

The TPX 252 with its lateral sliding inking mechanism is a special machine!

Request a TPX 252 brochure (pdf):