Machine and system control

With the increasing complexity of pad printing solutions due to the integration into production lines, new demands are also being placed on the control systems of our machines and systems. This is due to the addition of supplementary functions such as vision systems for position control or print image monitoring, etc. We at Teca-Print support this important step, because in our digital world it is essential to offer efficient software solutions for process reliability and process stability.

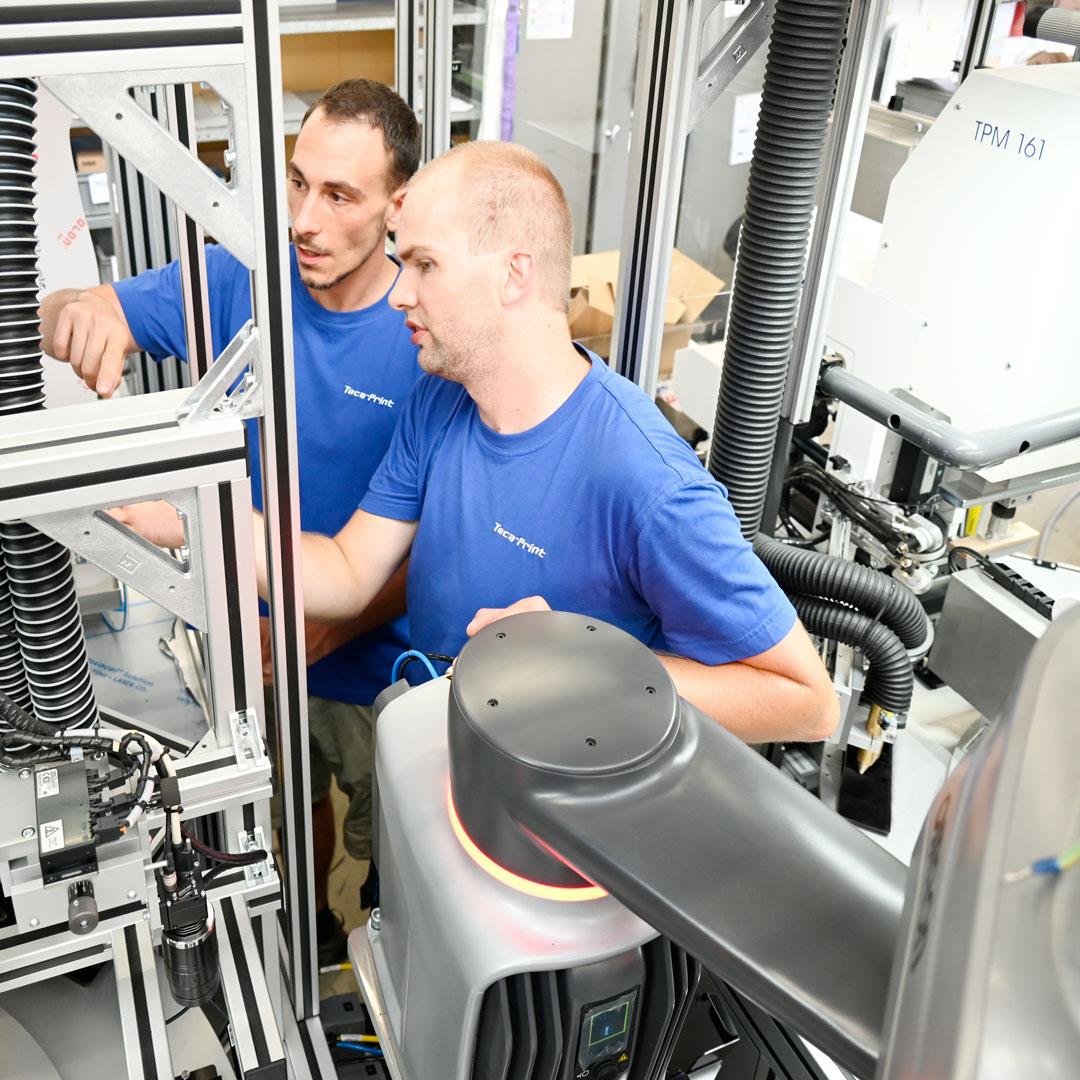

Our team of software experts is constantly growing. We programme our machines and systems ourselves and respond flexibly to your requirements and wishes.

Whether you want to integrate your Teca-Print pad printing machine directly into your injection moulding line, into another assembly line or connect it to other peripherals, we can offer you the appropriate solution.

You can rely on our expertise and flexibility.

Interfaces: Connect and benefit

Complex systems require an efficient and reliable communication solution. This is the basis for flawless technical interaction between the components. Only in this way can the individual modules of an automation solution work together perfectly and provide their full performance.

At Teca-Print, we respond flexibly to the wishes and requirements of our customers. We are also happy to recommend a solution that suits your application.

We work with various high-performance Ethernet fieldbus technologies. Examples include EtherCAT, EtherNet/IP, PROFIBUS and Profinet. We are also happy to realise solutions with pure point-to-point communication (IO) for you.

For automation systems whose communication solution is based on Ethernet, we offer extended functions such as OPC UA (Open Platform Communications United Architecture), particularly with regard to Industry 4.0. You also benefit from real-time communication with external workstations such as computers and receive all data on the application, machine status and error or warning messages.

We implement and integrate new technologies.

Latest technology even for our standard machine series

It’s not only for the construction of complex systems that we rely on technologically up-to-date products. We are also continuously developing our series machines.

We like to utilise new technical possibilities in order to increase user-friendliness for our customers and to deliver a technically advanced product at all times.

We are currently in the process of equipping a large number of our standard machine series with a new, even better control system. You benefit from intuitive operation and a display with colour-coded elements. This makes the operation of even highly technical products a positive experience for every user.

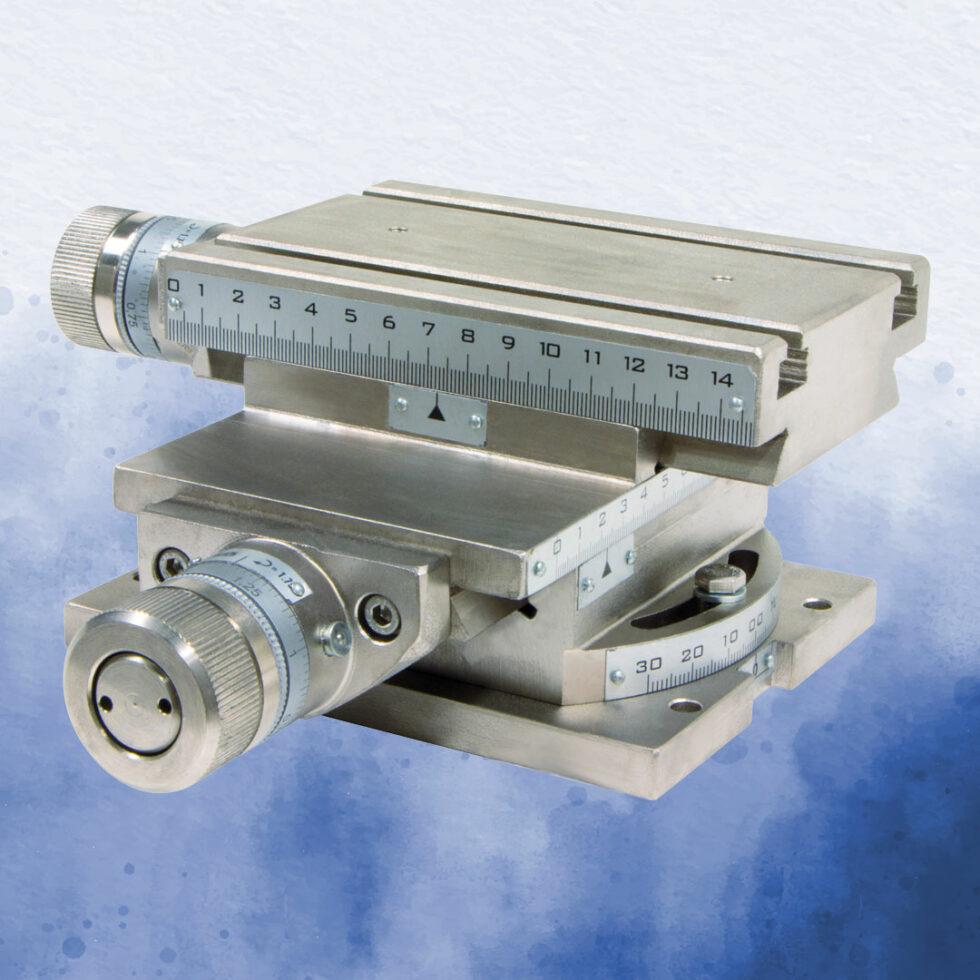

Our electromechanical TPX machines in particular give you the flexibility to customise your printing process.

Motivate your team with our high-performance, user-friendly pad printing machines.

We develop and produce for you! Customised and tailor-made. Safe and reliable.

Interfaces have been an important topic at Teca-Print for decades. In the beginning, these were mostly straightforward interfaces, e.g. to a small peripheral device. Our knowledge has grown with the continuous development, so that our employees can also program very complex interfaces for automation. We are your competent partner for customer-specific projects.

Please contact us using the contact form, by e-mail or phone. We will be happy to send you further information or advise you personally.