Pre- and post treatment

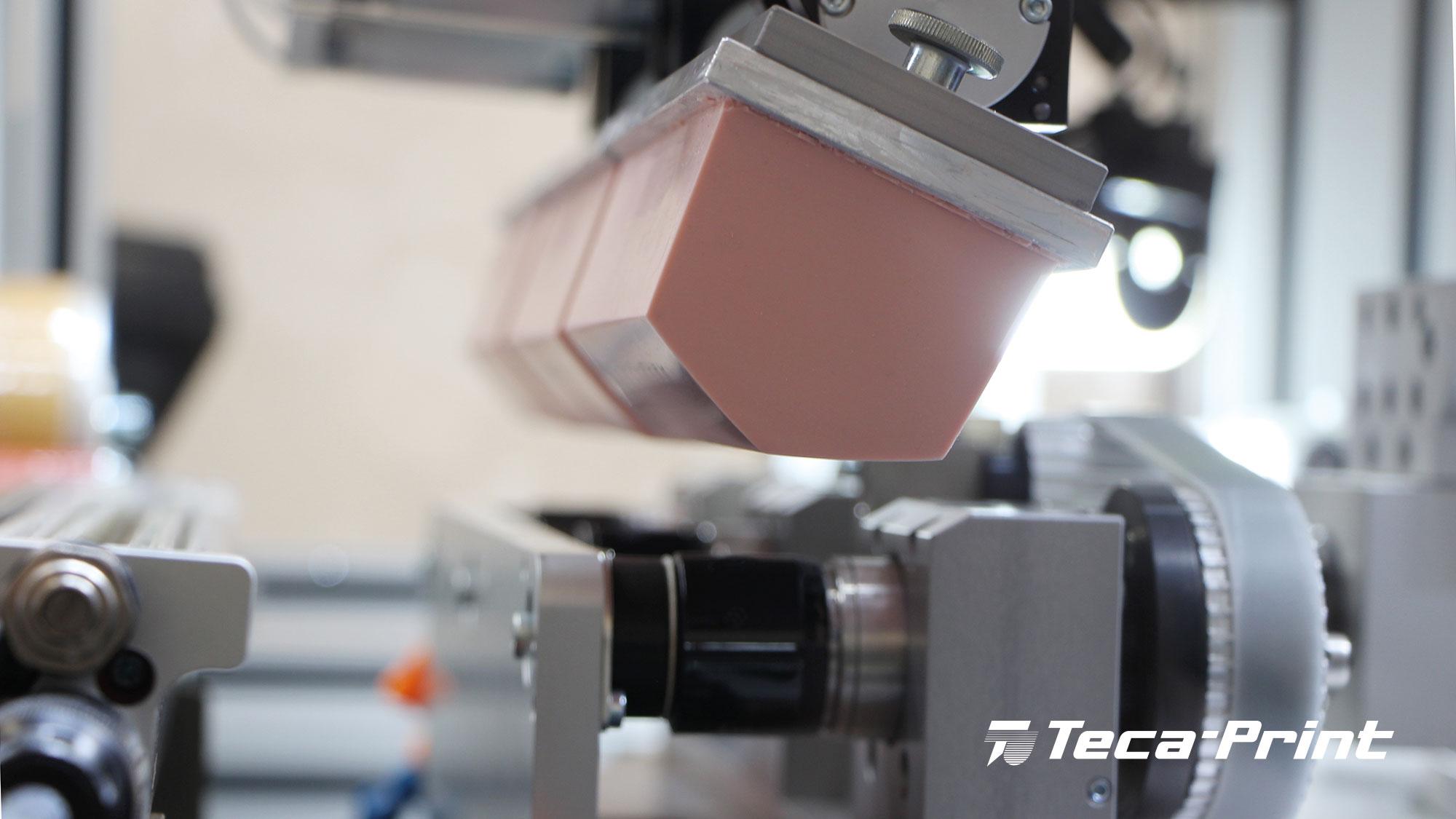

Pad printing is a very versatile printing process – the applications and the materials that are printed on are correspondingly diverse.

In order to achieve good adhesion, some materials require pre- and/or post-treatment. Some plastics, for example, have too low a surface tension to allow the ink film to cross-link or adhere. Pre-treatment of the surface to be printed is necessary to obtain the required tension. Post-treatment, particularly with heat, is also sometimes necessary or accelerates the drying process.

Our peripheral devices for pre- and post-treatment are the perfect complement to our printing machines.

Pre-treatment is absolutely essential for some materials.

Post-treatment is also helpful in many cases for faster drying or to enable hardening at all, depending on the type of ink used, application and specifications.

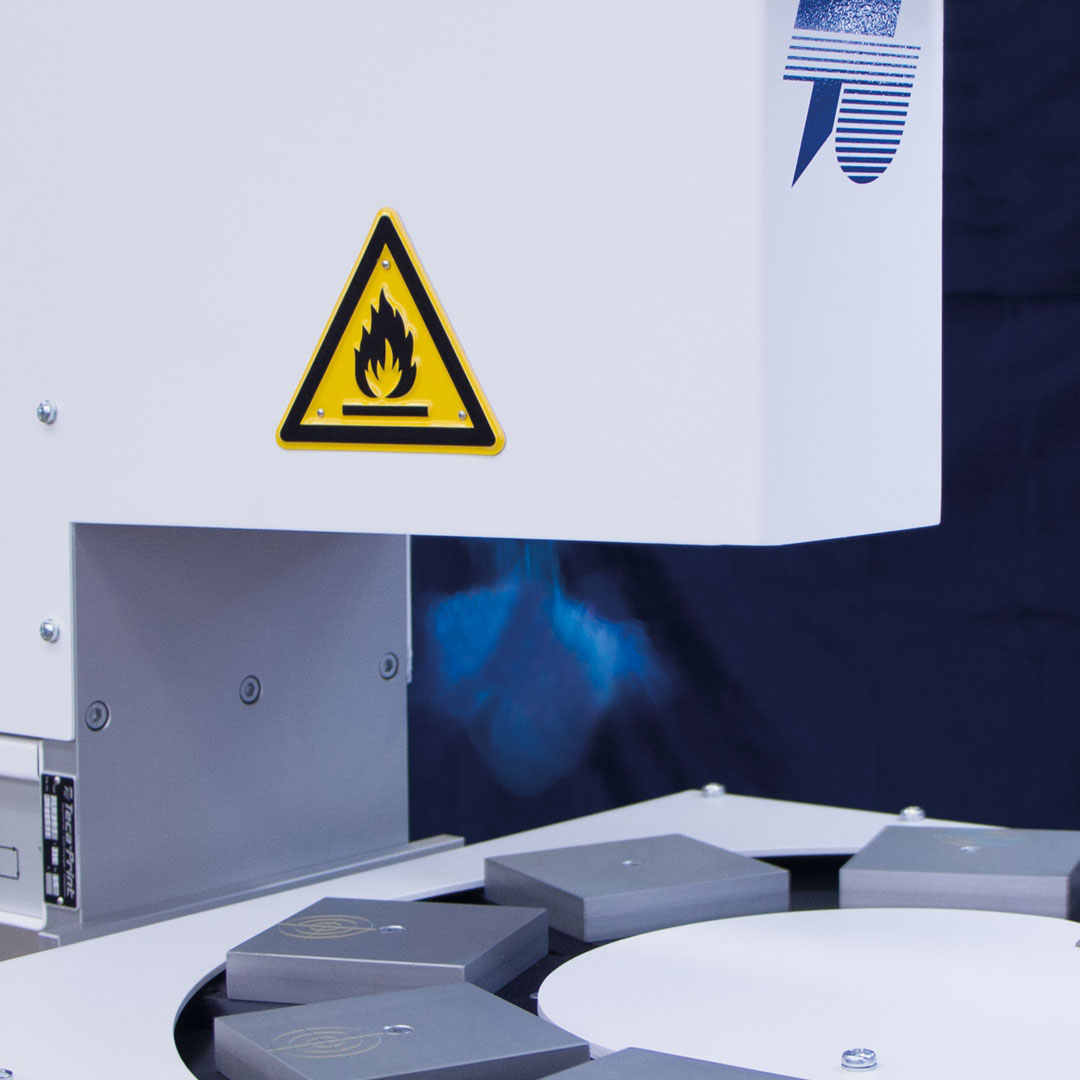

FLG 201/202

Flame treatment units (pre-/post-treatment)

FLG 201/202

The FLG 201 and FLG 202 flame treatment units are used for the pre-treatment of certain plastics (PE, PP) and for post-treatment in pad printing. In many cases, surface flaming is what makes printing possible at all.

IRG 101

for post-treatment and drying

IRG 101

The IRG 101 infrared drying unit has been developed for post-treatment, i.e. drying the ink film on certain materials (e.g. glass, metal, plastics). It is operated with short-wave infrared rays.

Corona

Pre-treatment

Corona

During pre-treatment with corona, the surface is energised with electrons and ions, causing a change in charge and increasing the surface tension. This ensures better cross-linking with the printing ink.

Plasma

Pre-treatment

Plasma pre-treatment

Plasma pre-treatment is usually also suitable for high-gloss surfaces and is based on the finest cleaning of the surface of organic particles combined with simultaneous activation, so that the cross-linking with the surface is given.

Ionisation

Pre-treatment

Ionisation

Electrostatic charge, which is either present on the printing pad or the object to be printed or is caused by the deformation of the printing pad, can lead to thin strips being pulled out of the ink film. This electrostatic charge can be counteracted by ionisation.

Hot air

Post-treatment

Hot air drying

Drying the freshly printed parts with hot air accelerates the evaporation of solvents from the ink film. The parts can be piled, packaged or combined as bulk goods more quickly.

NIR

Post-treatment

NIR drying

NIR drying works with short-wave infrared rays that penetrate deep into the ink film and dry it from the inside out within fractions of a second. The heating is homogeneous. NIR drying is considered to be energy-saving and very efficient.

LED UV drying

Post-treatment

LED UV drying

In some cases, LED UV printing ink is used in pad printing. This requires LED UV drying that is customised to the print object and print image size. Drying is a photochemical process that is completed within fractions of a second.

Flame treatment units FLG 201 and 202

Our own development and production – ideal for pad printing

Flame treatment unit FLG 201

The flame treatment takes place during a defined length of time following an impulse signal or during an active signal.

The flame treatment units FLG 201 and FLG 202 work with a gas flame and are used in pad printing for the pretreatment of certain plastics (PE,

PP) as well as for posttreatment.

In many cases printing is only possible if the surface was treated. With both units the flame treatment takes place when the workpiece passes under the gas flame. They are suitable for various applications and can be mounted to linear conveyor belts, rotary indexing tables or to a transfert carré. The flame width can be either 125 mm or 200 mm.

Flame treatment unit FLG 202

The FLG 202 flame treatment unit has a programmable safety control, emergency stop switch and monitoring of compressed air and gas.

The duration of the flame treatment is adjustable via a user-friendly switch. Alternatively the flame duration can be determined by an external signal.

Our flame units work with natural gas

Our pre- and post-treatment devices supplement our pad printing machines with the necessary functions depending on the ink type, material to be printed or specific adhesion requirements. All devices are harmonised with our range of machines and are continuously developed and adapted to technical innovations.

We will be happy to answer any questions you may have. Please contact us using the contact form, by e-mail or phone.