delta III TPF 451

Your advantage:

- 1 to 6 colours

- high printing force

- servo drive control

- sustainable production

- sealed inking system

- a wide range of peripheral devices available

Modern, with a focus on the essential: The electromechanical machines of the line delta are suitable for a wide range of applications at an excellent price/performance ratio and with a clear range of options.

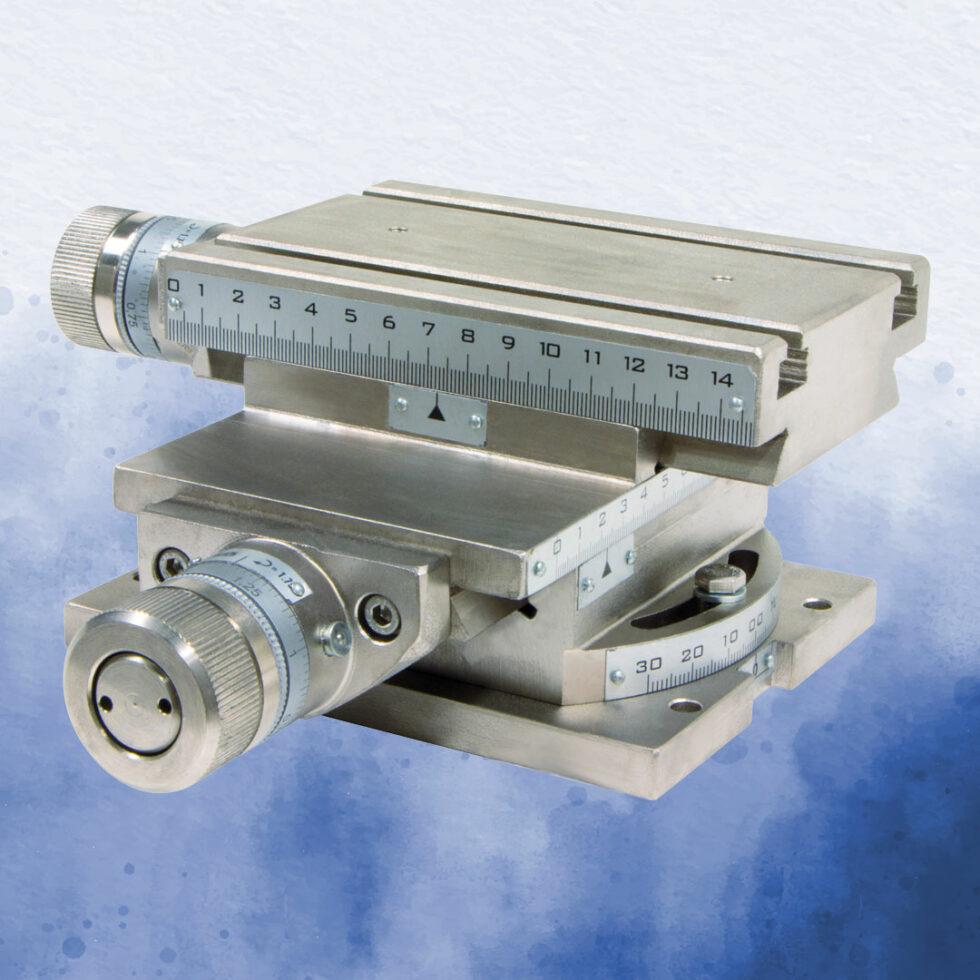

With a plate width of up to 450 mm and a plate depth of 220 or 270 mm, high quality prints in up to five colours can be produced with the sealed inking system. All settings can be entered easily using the touch screen. Self-explanatory symbols and the use of colour ensure a high level of user-friendliness. Next to the automatic pad cleaning device, different machine bases and profile frames as well as peripherals are available as options.

The delta III TPF 451 pad printing machine can be equipped with the Transfer Carré for multi-colour printing in large quantities.

Work on the modern pad printing machine is carried out with great pleasure and passion.

Most customers use the delta III TPF 451 pad printing machine with sealed inking system in combination with integrated pad cleaning.

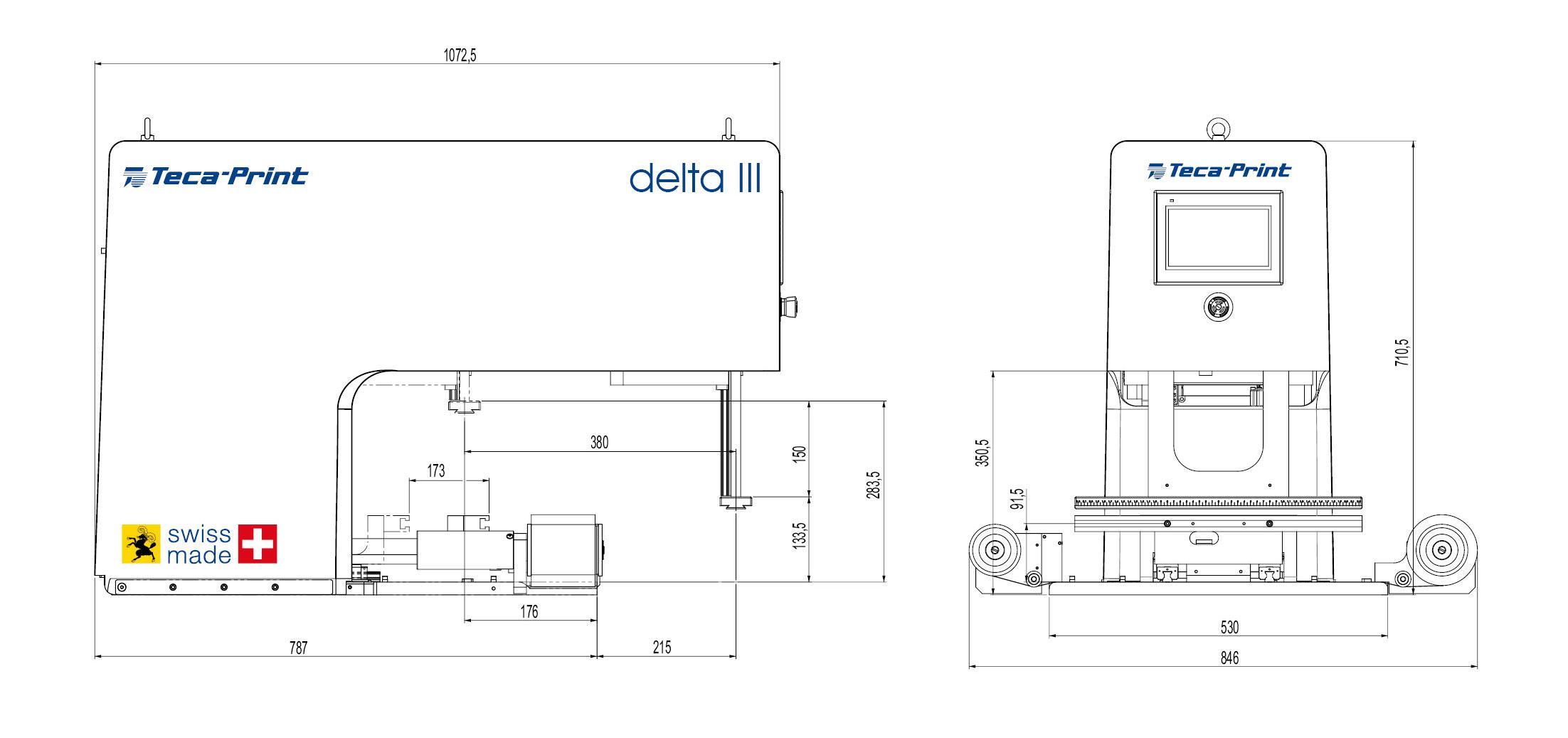

Technical data delta III TPF 451

Number of colours:

1 to 6 colours

Ink cup sizes:

Ø 56 mm, Ø 65 mm, Ø 72 mm, Ø 86 mm, Ø 96 mm, Ø 105 mm, Ø 115 mm, Ø 130 mm

Plate sizes:

standard plate widths: 100 / 150 / 250 / 320 / 350 / 450 mm

standard plate depths: 220 / 270 mm

Output:

up to 1’850 cycles per hour (pad stroke 20 mm)

Drive system:

electromechanical (3 axis control with 3 servo motors), infinitely adjustable parameters

Printing force:

3’000 N (printing force must be balanced)

Mains connection:

230 V / 50 Hz (5 – 6 bar air pressure)

Control:

PLC – HMI touchscreen

Vertical pad stroke:

electromechanical, 150 mm infinitely adjustable

Outreach pad carriage:

215 mm

Weight:

approx. 131 kg without base, approx. 300 kg with MS 352 machine base

Dimensions (WxHxD):

530 x 710 x 1073 mm

Benefit from the advantages of the electromechanical delta III with an optimum price/performance ratio

Request a delta III TPF 451 brochure (pdf):