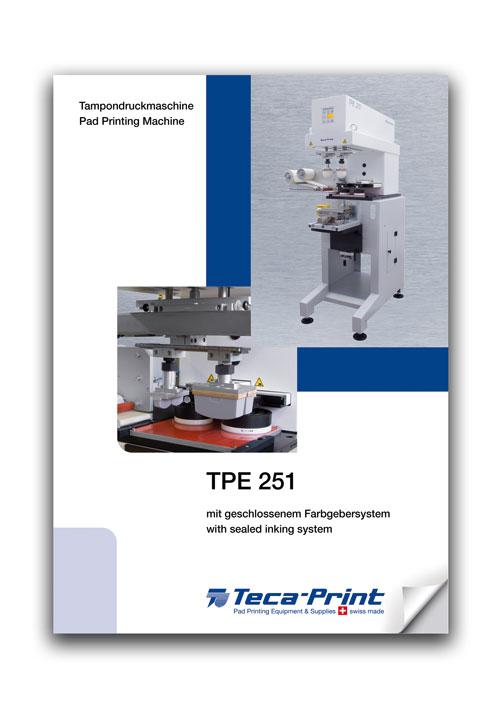

TPE 251

Your advantage:

- “middle sized” machine design

- up to 4 colours possible using round ink cups

- can be equipped with oval ink cups as well

- electropneumatical

- wide range of accessories and peripheral devices

- as TPE 250 available with open inkwell system

The pad printing machine TPE 251 with electro-pneumatic drive and equipment for the sealed inking system, offers versatile application possibilities at a convincing price-preformance ratio. Thanks to features such as an easy to understand compact PLC control unit and a quick-change system for inks and plates, the TPE 251 meets all requirements of a modern, user-friendly pad printing machine.

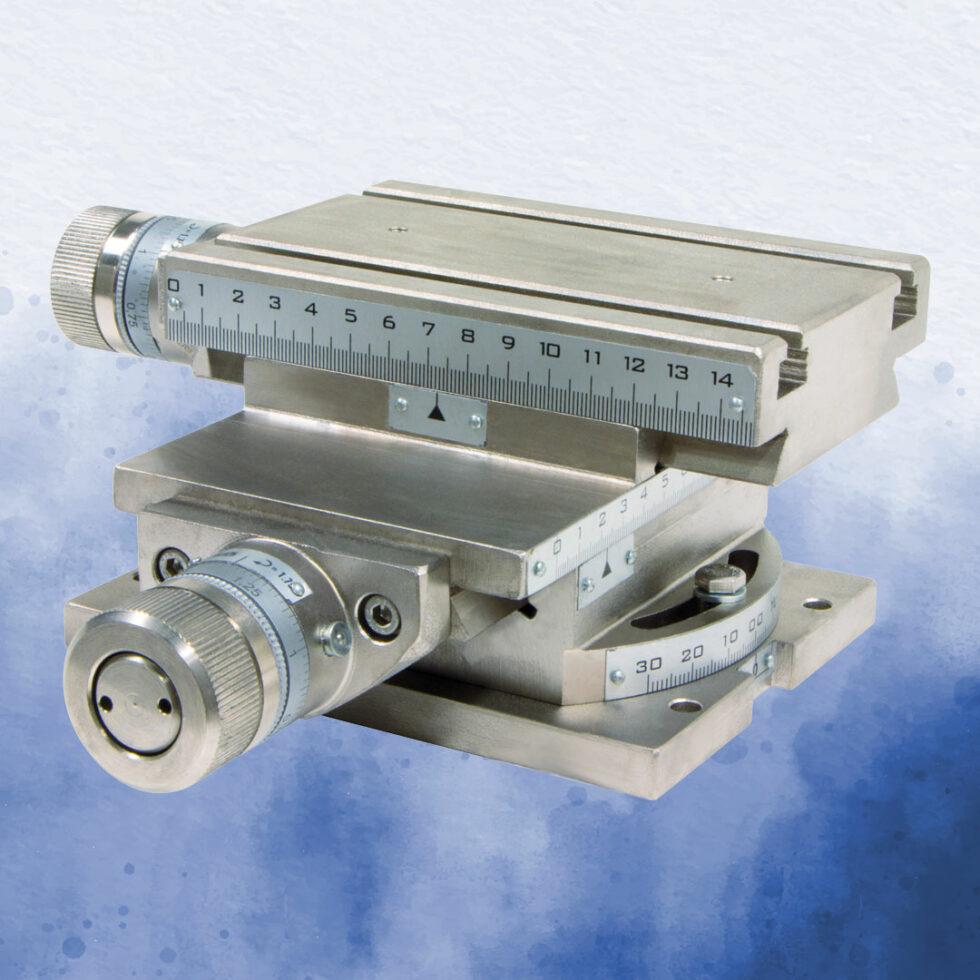

The practical ink cup holder with bayonet lock or the optional electric rotating cup cylinder are available for cup fastening.

As a pad printing machine in the medium size range, the TPE 251 proves to be a practical all-rounder that is available with many extras e.g. the automatic pad cleaning device.

The pad sliding device moves the printing pads from the first colour to the second colour. The result is a two-colour print.

Assembly of a system with four TPE 251 pad printing machines – our employees are committed and work very precisely.

In addition to many other peripheral devices, a rotary table can also be attached to the TPE 251.

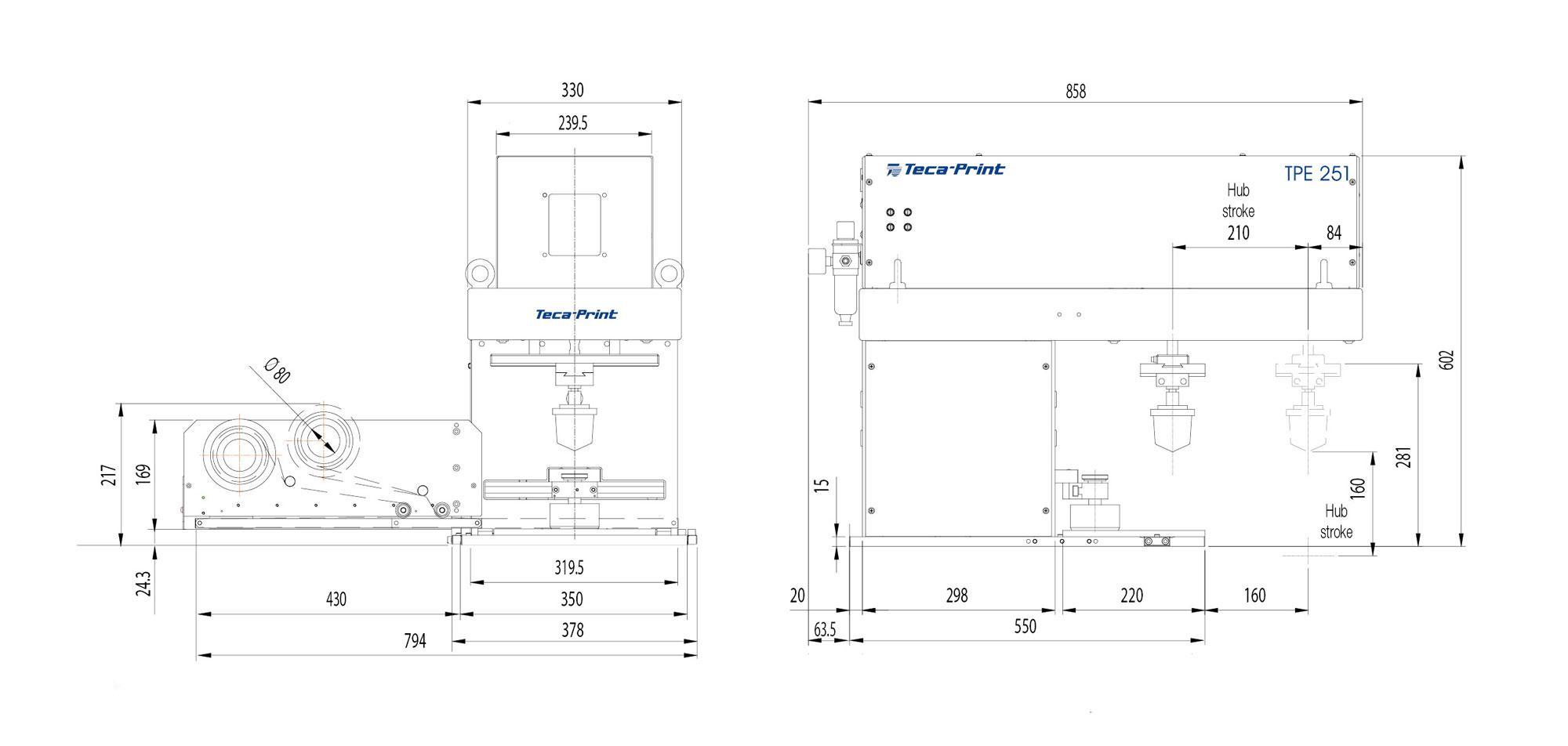

Technical data TPE 251

Number of colours:

max. 4 colours

Ink cup sizes:

Ø in mm: 56 / 65 / 72/ 86 / 96 / 105 / 115,

oval in mm: 140 x 070 / 120 x 096

Plate sizes:

plate widths 100 / 150 / 250 oder 350 mm, plate depths 220 oder 350 mm

Output:

up to 1’400 cycles per hour

Drive system:

electropneumatical

Printing force:

1’150 N (printing force must be balanced)

Mains connection:

230 V / 50 Hz, 5 – 6 bar air pressure

Air consumption:

0.9 litres / cycles at 6 bar

Control:

PLC

Weight:

approx. 82 kg without base

approx. 148 kg with MS 250 machine base

Dimensions (WxHxD):

350 x 602 x 858 mm

The TPE 251 is popular both for manual workstations and for integration into systems.

Request a TPE 251 brochure (pdf):