TPX 100

Your advantage:

- 1 or two colours

- highest precision and accuracy

- electropneumatical

- compact design

- open inkwell system

- available as “édition cadrans”

The TPX 100 pad printing machine with open inking system impresses as a small, compact machine with high-precision printing performance and modern PLC control.

The TPX 100 is therefore used wherever the best performance is required for smaller print formats. Highest printing and repeat accuracy are a matter of course for the electro-pneumatically driven machine, which is often used as a manual workstation.

A coloured touchscreen enables clear, user-friendly operation.

An extensive range of peripheral equipment is available for the TPX 100, such as the automatic thinner injection, a rotary table or shuttle table, a pad sliding device, etc.

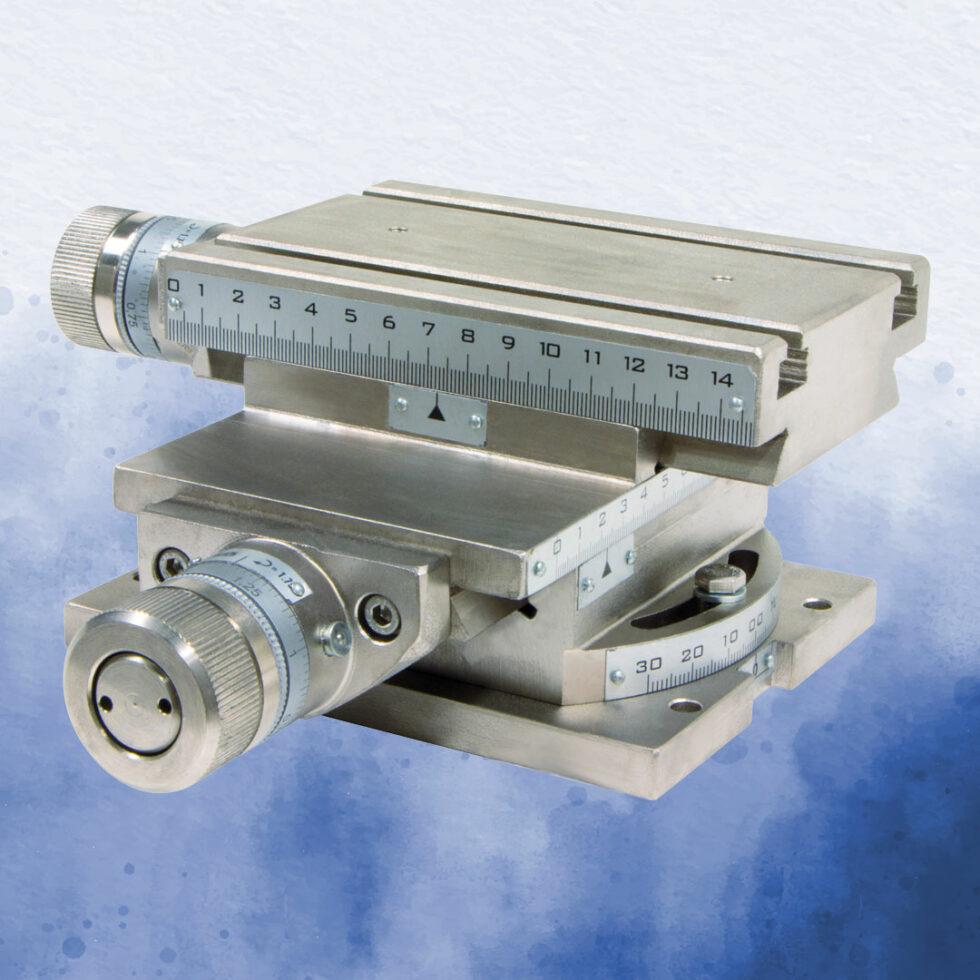

The TPX 100 can of course also be combined with various accessories such as a machine base or coordinate table.

The TPX 100 pad printing machine is a compact printing machine for high-precision printing applications.

Our team assembles the high-quality TPX 100 with the greatest care and passion.

The TPX 100 pad printing machine is also available as an “édition cadrans”, with special features for the watch industry.

Technical data TPX 100

Number of colours:

1 or 2 colours

Plate sizes:

standard plate width: 80 / 100 / 130 mm

standard plate depths: 80 / 100 mm

Output:

up to 1’800 cycles per hour

Drive system:

electropneumatical

Repeat accuracy:

< ± 0.02

Printing force:

250 N (printing force has to be balanced)

Mains connectione:

230 V / 50 Hz, 5 – 6 bar air pressure

Air consumption:

0.5 litres / cycle at 6 bar

Control:

PLC – HMI touchscreen

Vertical pad stroke:

100 mm, 140 mm as special edition, electrical infinitely adjustable

Outreach pad carriage:

88 mm

Weight:

approx. 30 kg without machine base

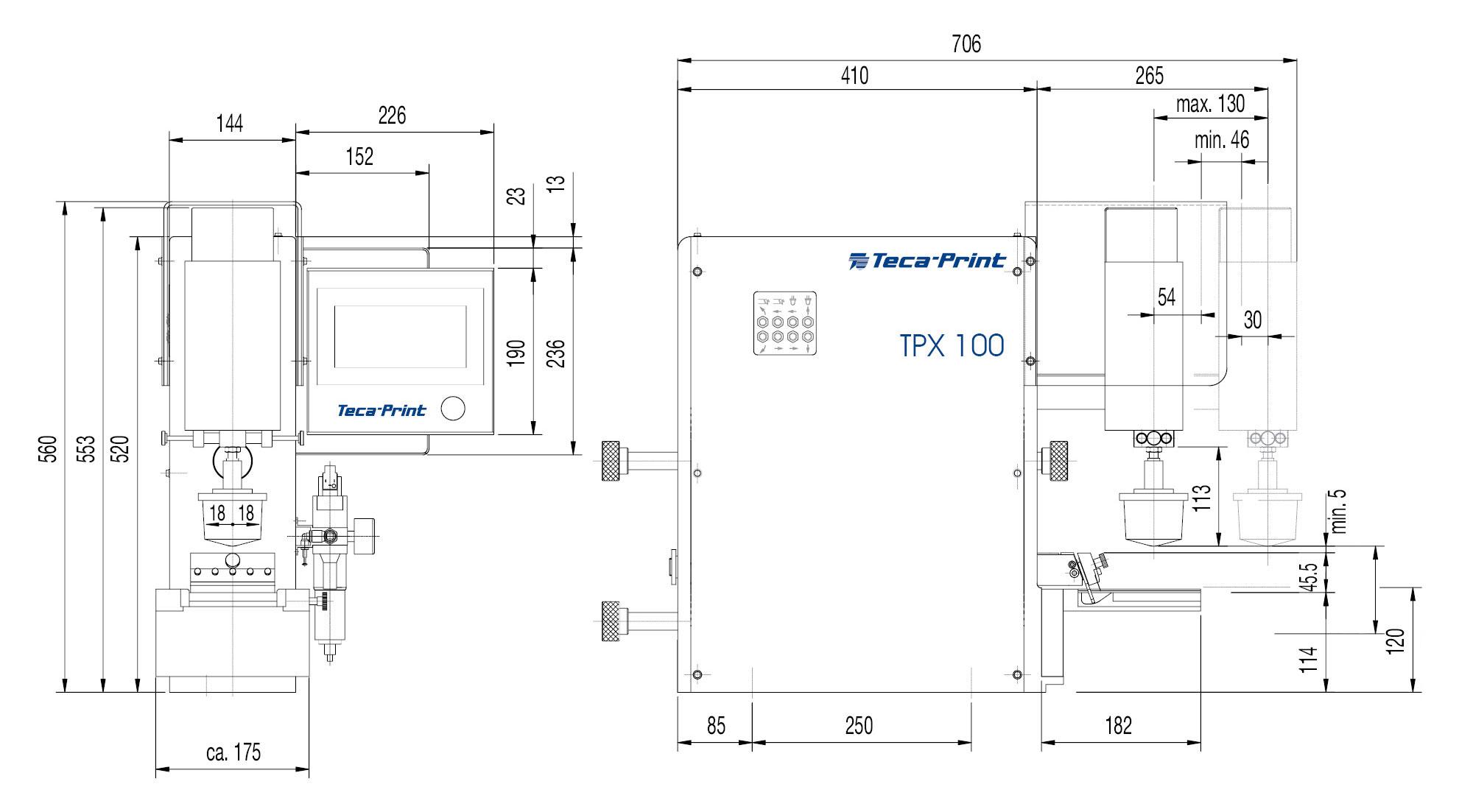

Dimenstions (WxHxD):

380 x 560 x 762 mm

The TPX 100 is a very special highlight among our pad printing machines: high performance and precision in a compact design

Request a TPX 100 brochure (pdf):