TPX 302

Your advantage:

- 1 or 2 colours possible

- particularly suitable for elongated print images

- highest flexibility

- servo drive control

- sealed inking system with lateral ink cup sliding

- a wide range of peripheral devices, accessories and software options available

The pad printing machine TPX 302 with a sealed inking system and lateral sliding ink cup is driven by three servo motors. This offers a highly flexible printing process.

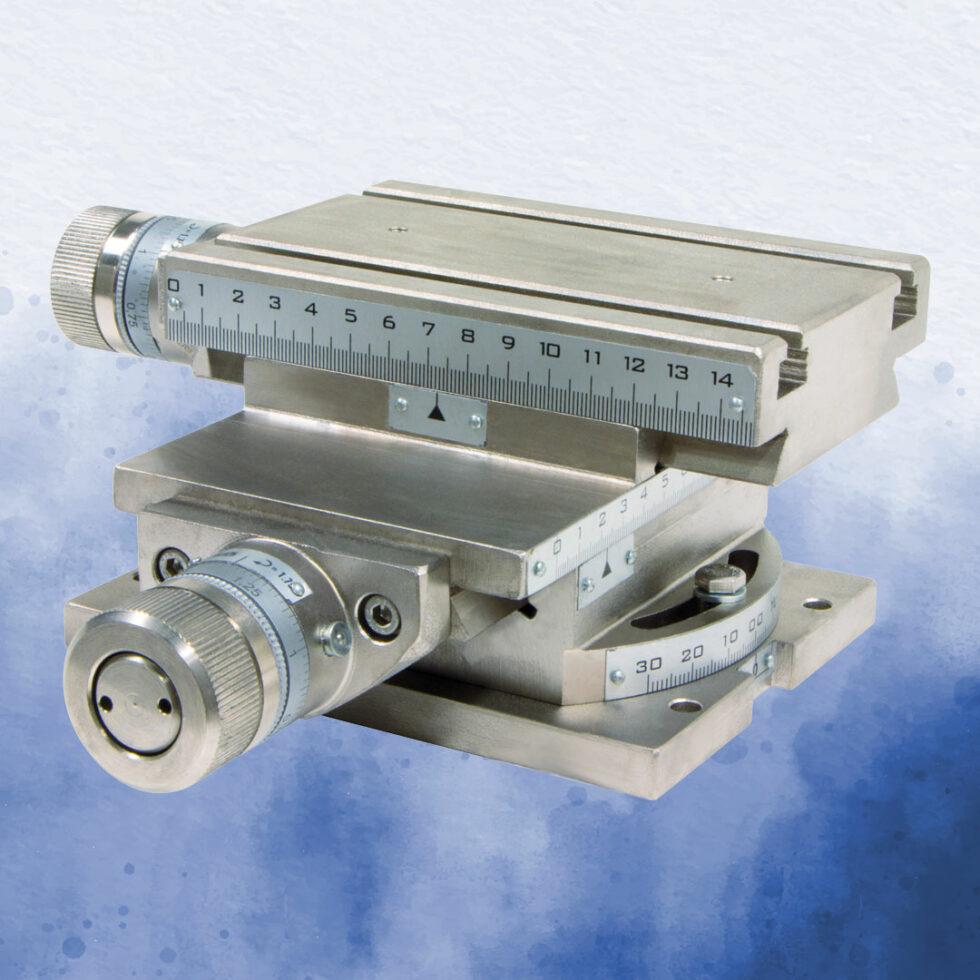

The operation can be controlled via the user-friendly colour touch-screen. Between the plate holder, adjustable in x- and w-axes and the pad stroke, which is infinitely variable horizontally and vertically, the TPX 302 is fully adjustable in all directions without the need of additional adjustment devices.

Additional characteristics of the TPX 302 are a spacious, flexible working area, an increased printing force and a very high print accuracy. An integrated pad cleaning device is available, that offers a maximum use of the cleaning tape thanks to the cleaning offset function.

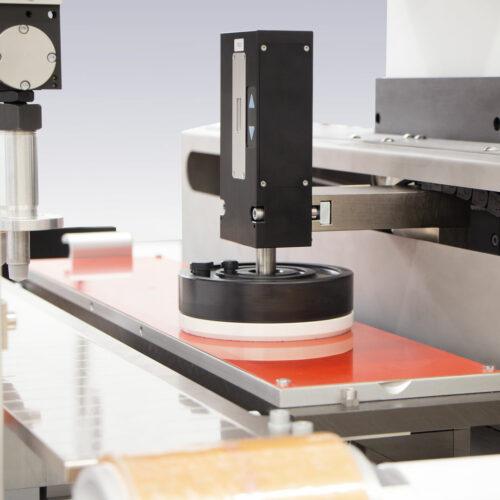

With the TPX 302, the ink cup moves sideways over the cliché. The ink can thus be distributed over a very long print image and picked up by one or more pads.

Our employees work with precision on the highly technical pad printing machines.

The TPX 302 offers excellent possibilities for integration into systems. The long print image can also be applied to a round object that is rotated around its own axis during printing.

Technical data TPX 302

Number of colours:

1 or 2 colours

Ink cup sizes:

Ø in mm: 56 / 65 / 72 / 86 / 96 / 105 / 115 / 130

Plate sizes:

standard plate widths: 450 / 600 mm

standard plate depths: 100 / 150 mm

Output:

up to 1’400 cycles per hour

Drive system:

electromechanical (3 axis control with 3 servo motors), infinitely adjustable parameters

Printing force:

4000 N (printing force must be balanced)

Mains connection:

230 V / 50 Hz, 5 – 6 bar air pressure required for some pneumatic accessories

Control:

PLC – HMI touchscreen

Vertical pad stroke:

electromechanical, 160 mm infinitely adjustable

Cliché plate adjustment:

± 4 mm (x-axis), ± 2° (rotation)

Weight:

approx. 220 kg without base, approx. 400 kg with MS 352 machine base

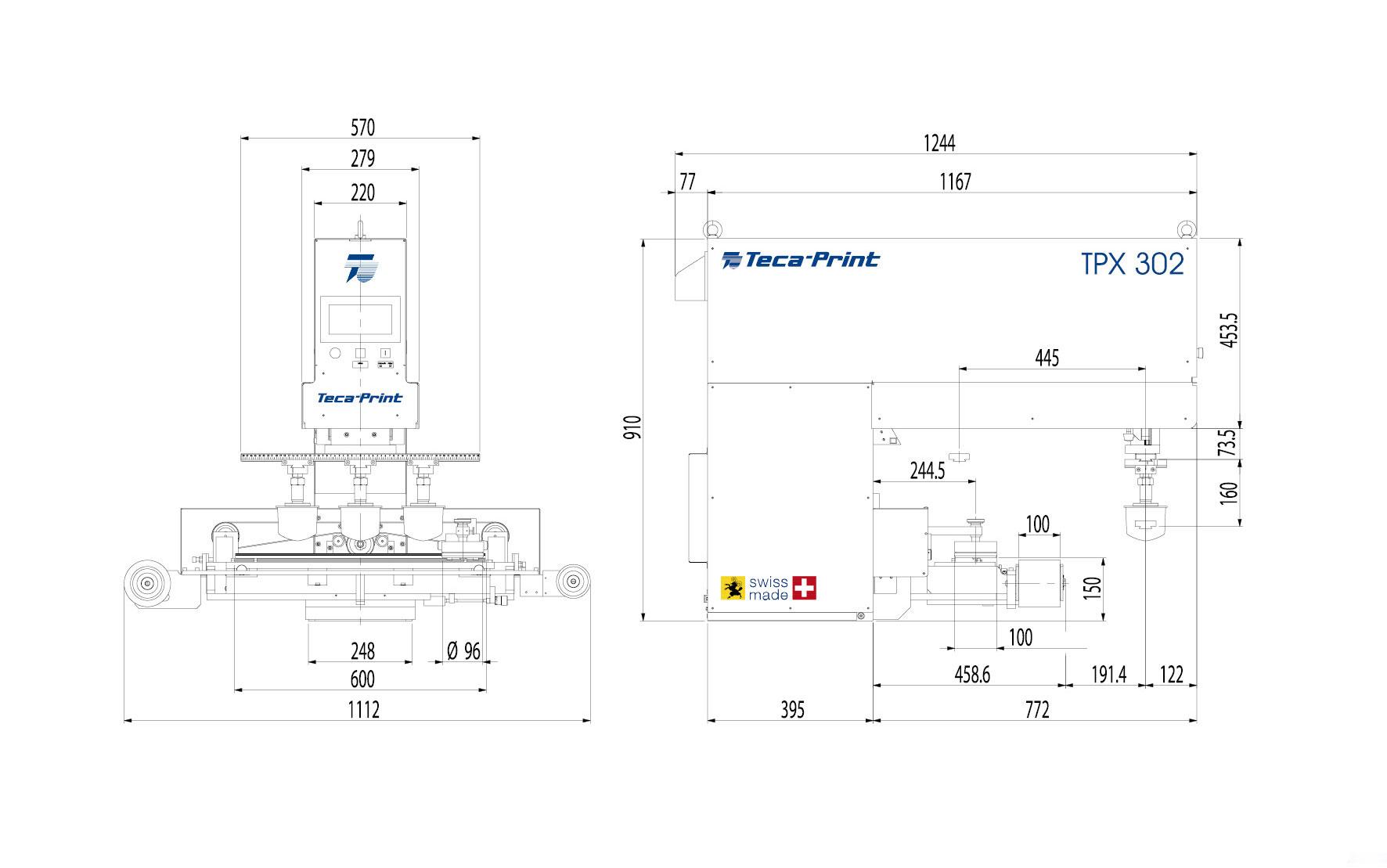

Dimensions (WxHxD):

1’112 x 912 x 1’244 mm (dimensions without base)

The TPX 302 is a modern pad printing machine that can also be used to realise special applications. We would be happy to advise you!

Request a TPX 302 brochure (pdf):