Production & assembly

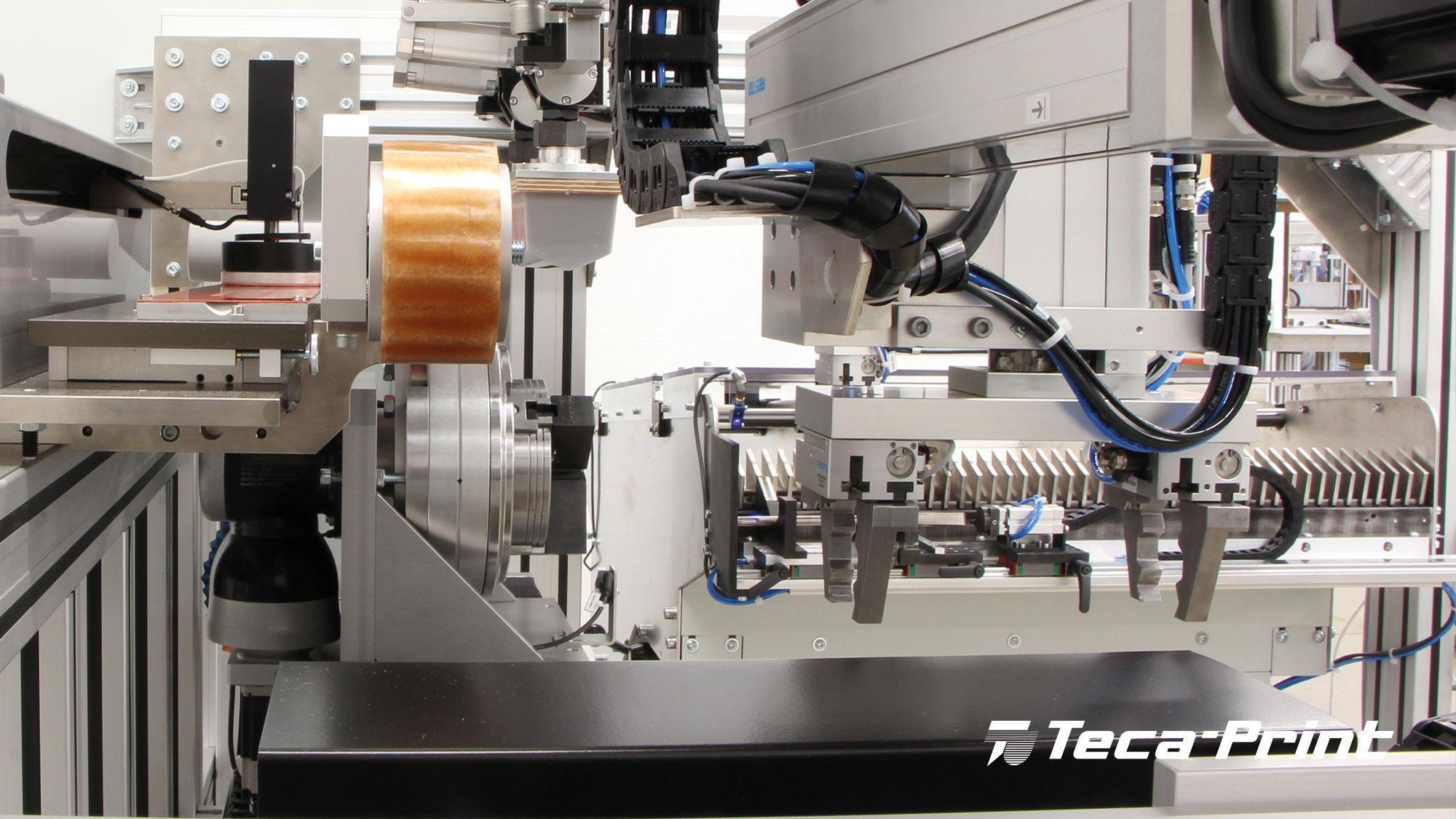

Once our systems have been designed and the various components have either been procured or produced in-house, assembly begins. Our mechanical fitters work hand in hand with design engineers, electronics engineers and software programmers. Our highly trained team always has access to the CAD data. This ensures that work on our highly complex systems is efficient and technically correct.

As our customer, you are welcome to view the current status of your system at any time. Good communication with you is very important to us at all times.

We rely on the expertise of our qualified team to assemble the customised pad printing systems developed for you. Internal and external training is an integral part of our strategy to ensure that our employees have up-to-date technical knowledge at all times.

At the same time, we promote young talent and, in addition to commercial and logistical trainees, have also been educating a trainee in the technical field since summer 2023.

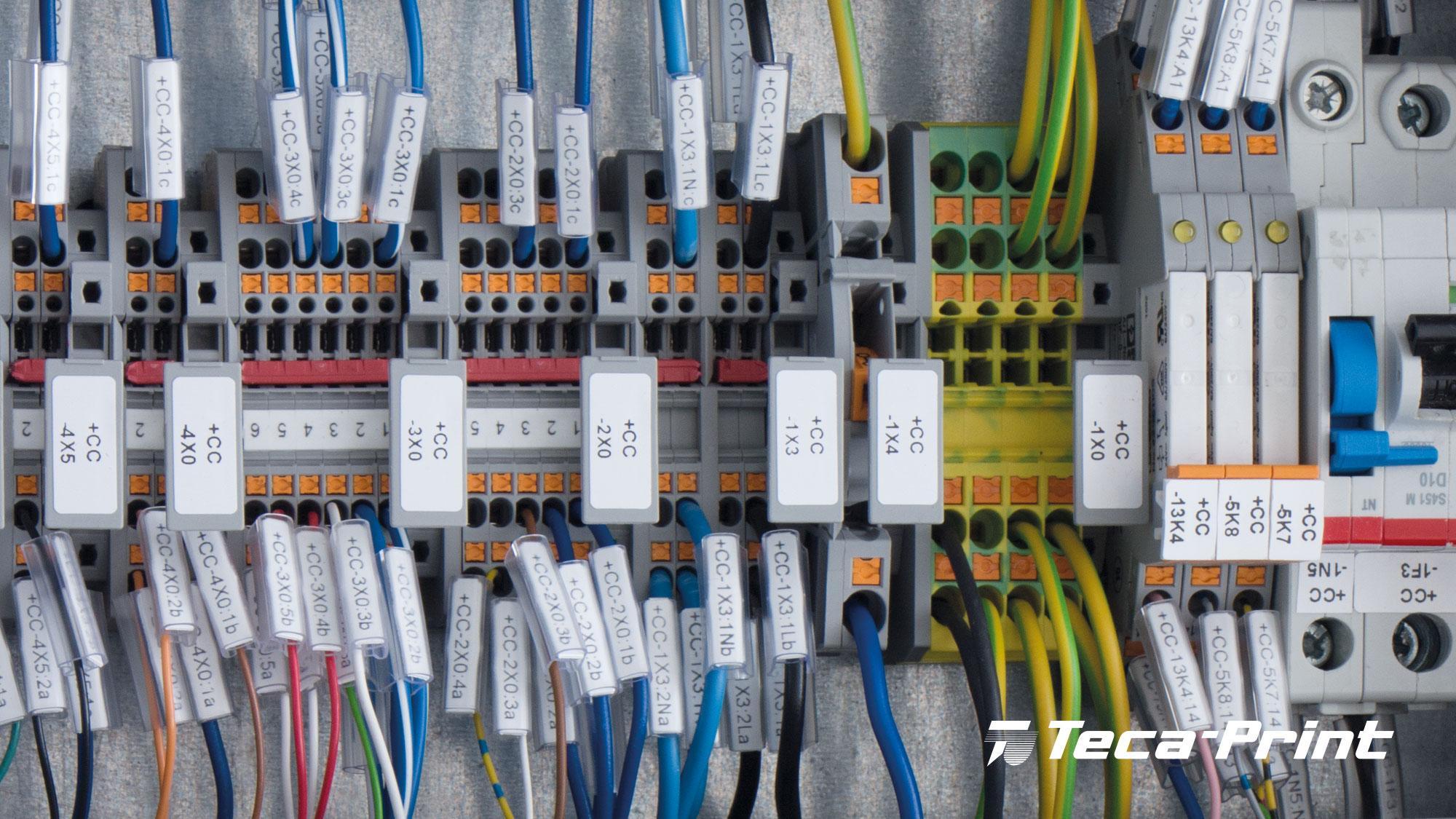

Our automation engineering department creates complex assembly plans for the electronic assembly of our customised systems. The control systems are assembled in-house and created in accordance with the current guidelines for mechanical engineering. Cable and wire labelling also allows quick and targeted intervention at a later stage.

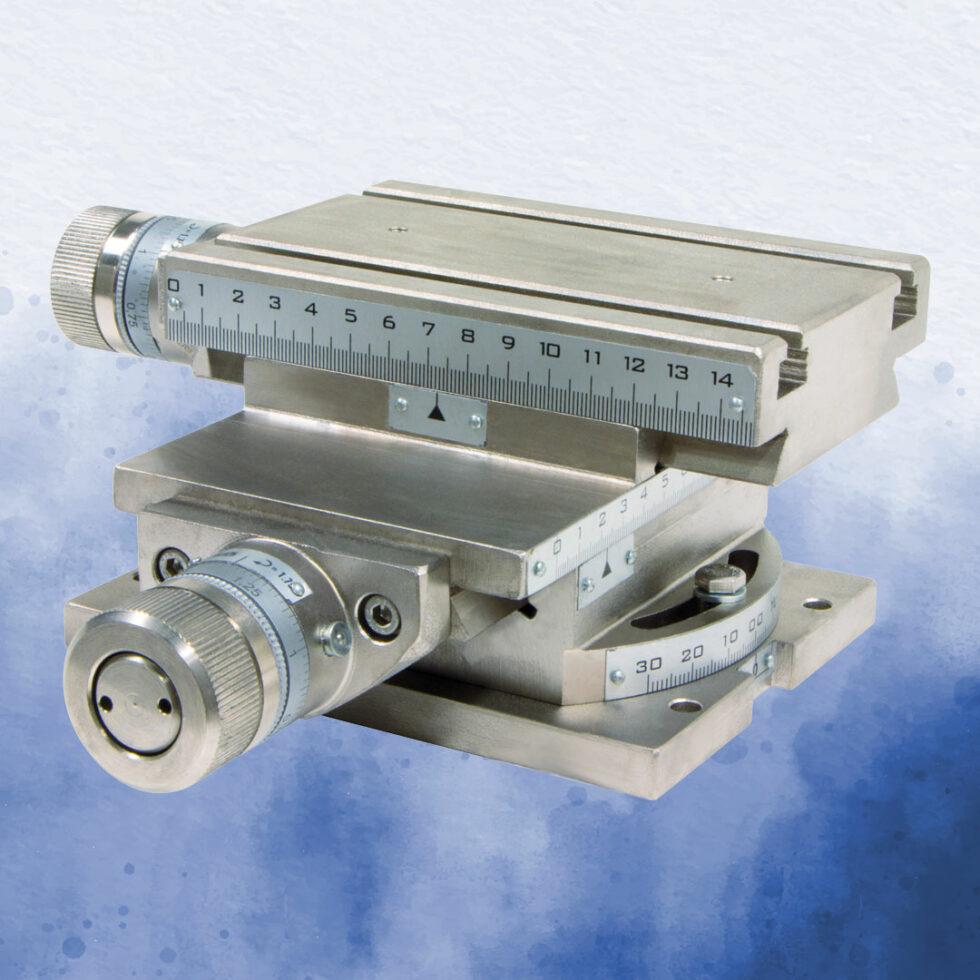

Our application department is involved in the production process as early as possible. This means that fine details can be taken into account and implemented right from the start.

Our team is motivated and up for every challenge!

You can rely on our experience and expertise. As a Swiss machine manufacturer, quality and precision are firmly anchored in our work and our products. We develop and build your system directly at our headquarters in Thayngen. From here, our high-quality products and systems reach the whole world.

We look forward to hearing from you using the contact form, by e-mail or phone. We will be there for further information and a personal consultation.