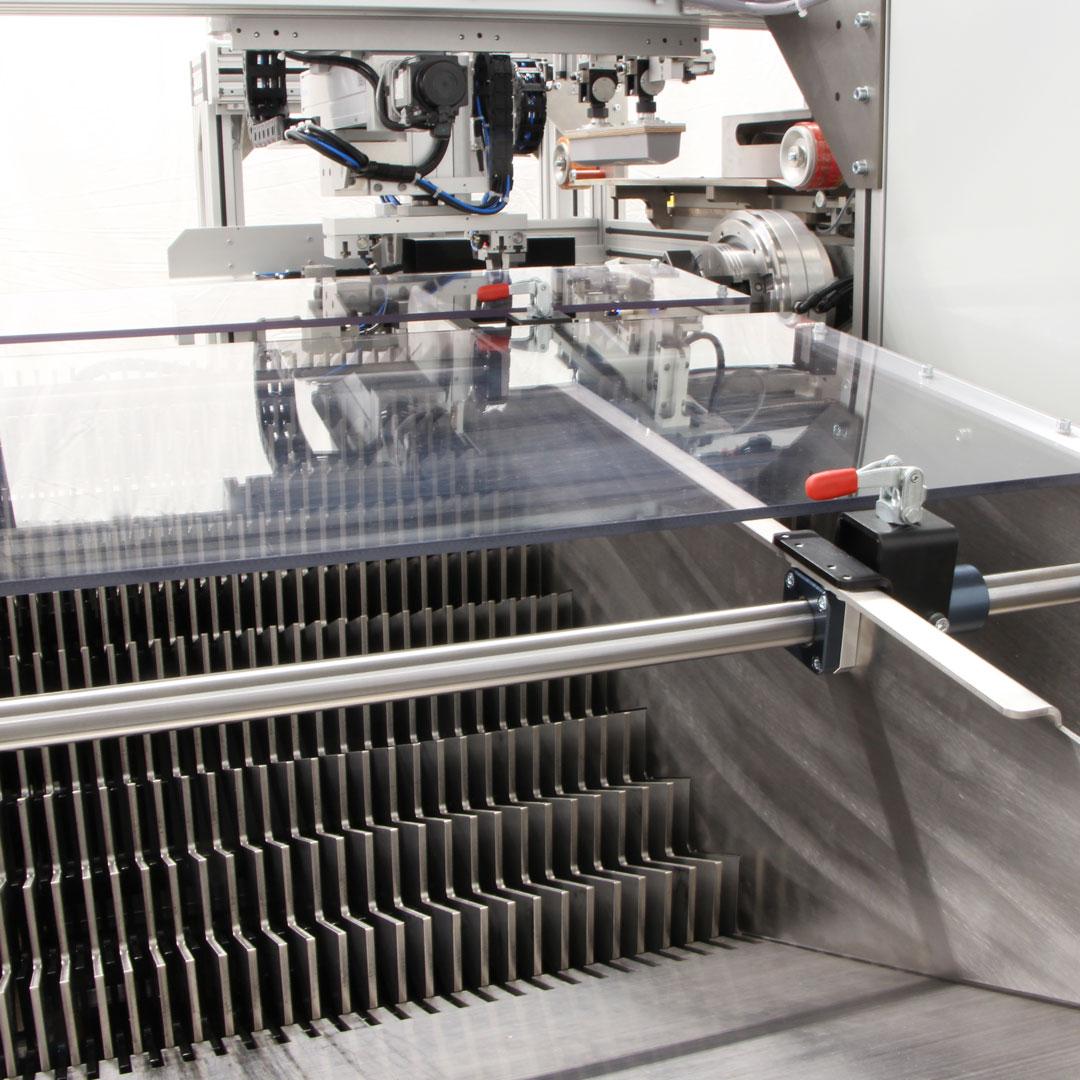

Customised and innovative – complete automated systems from the technology leader in pad printing

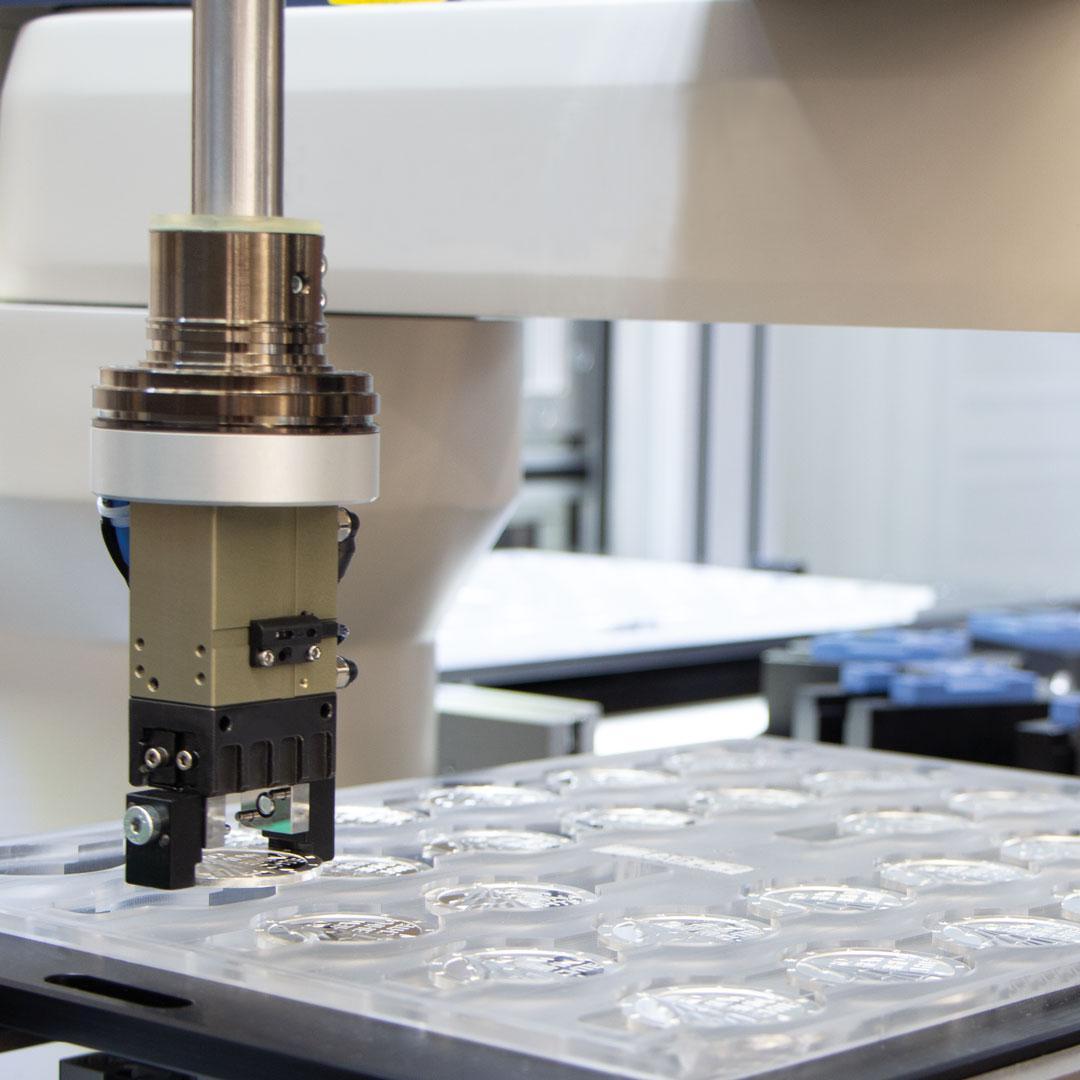

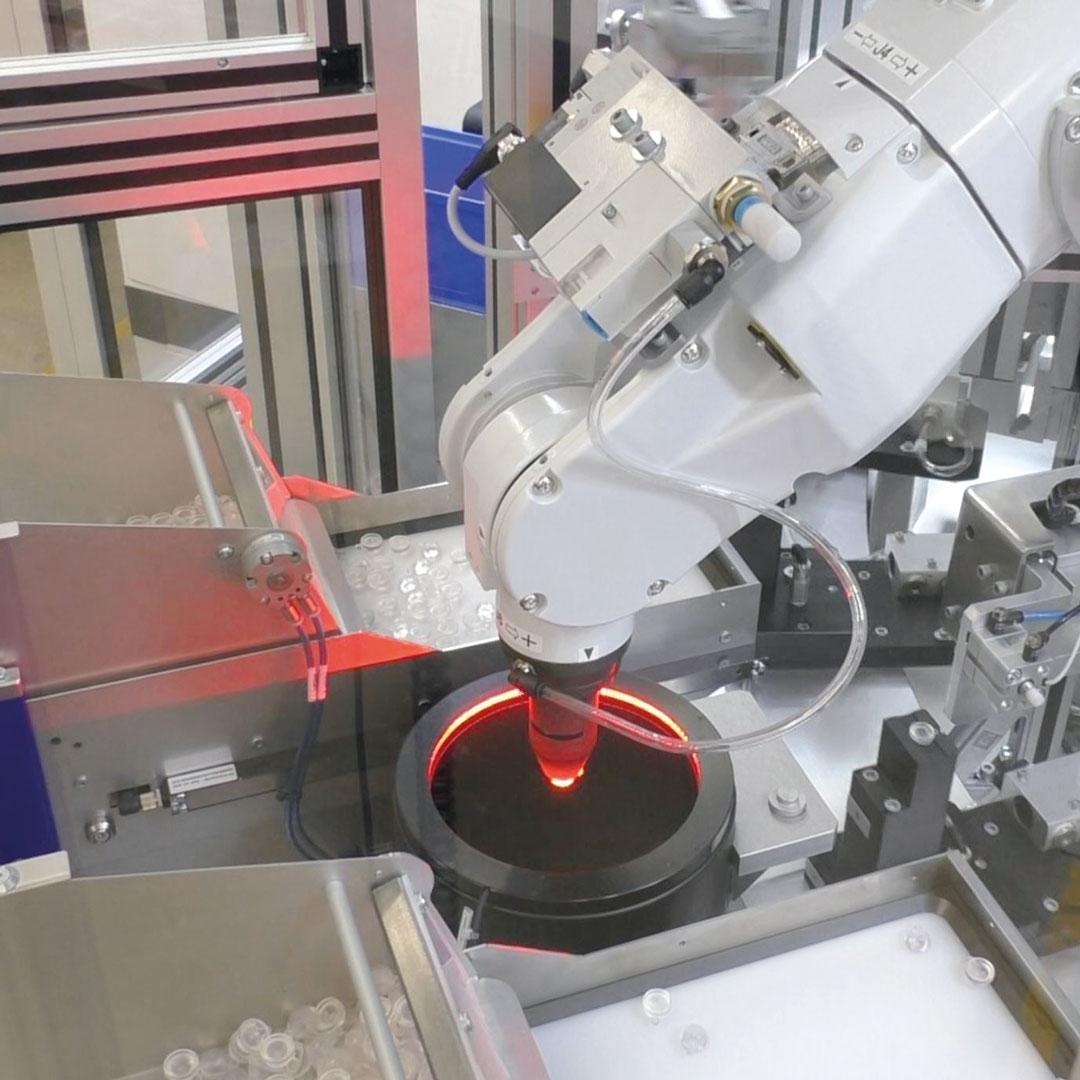

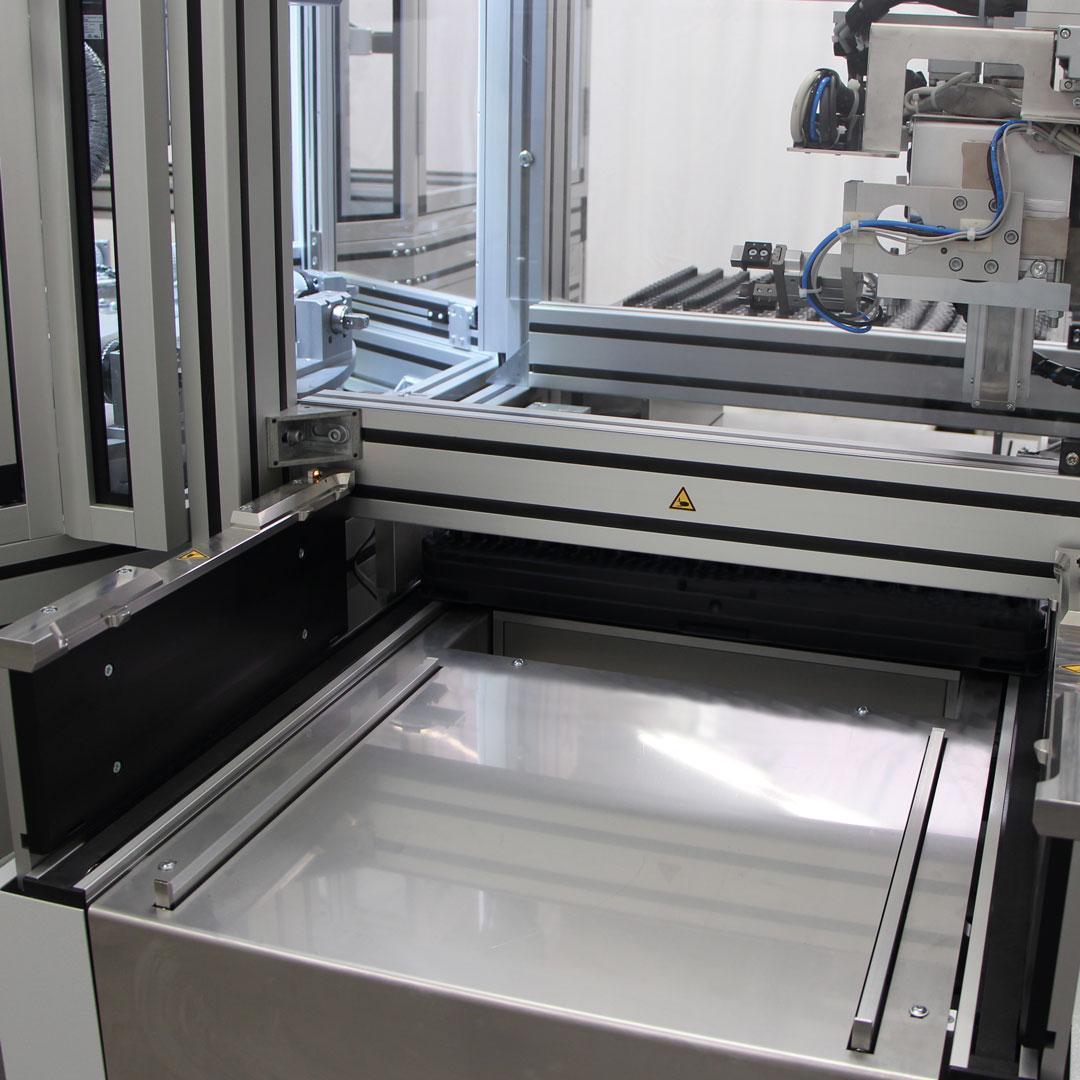

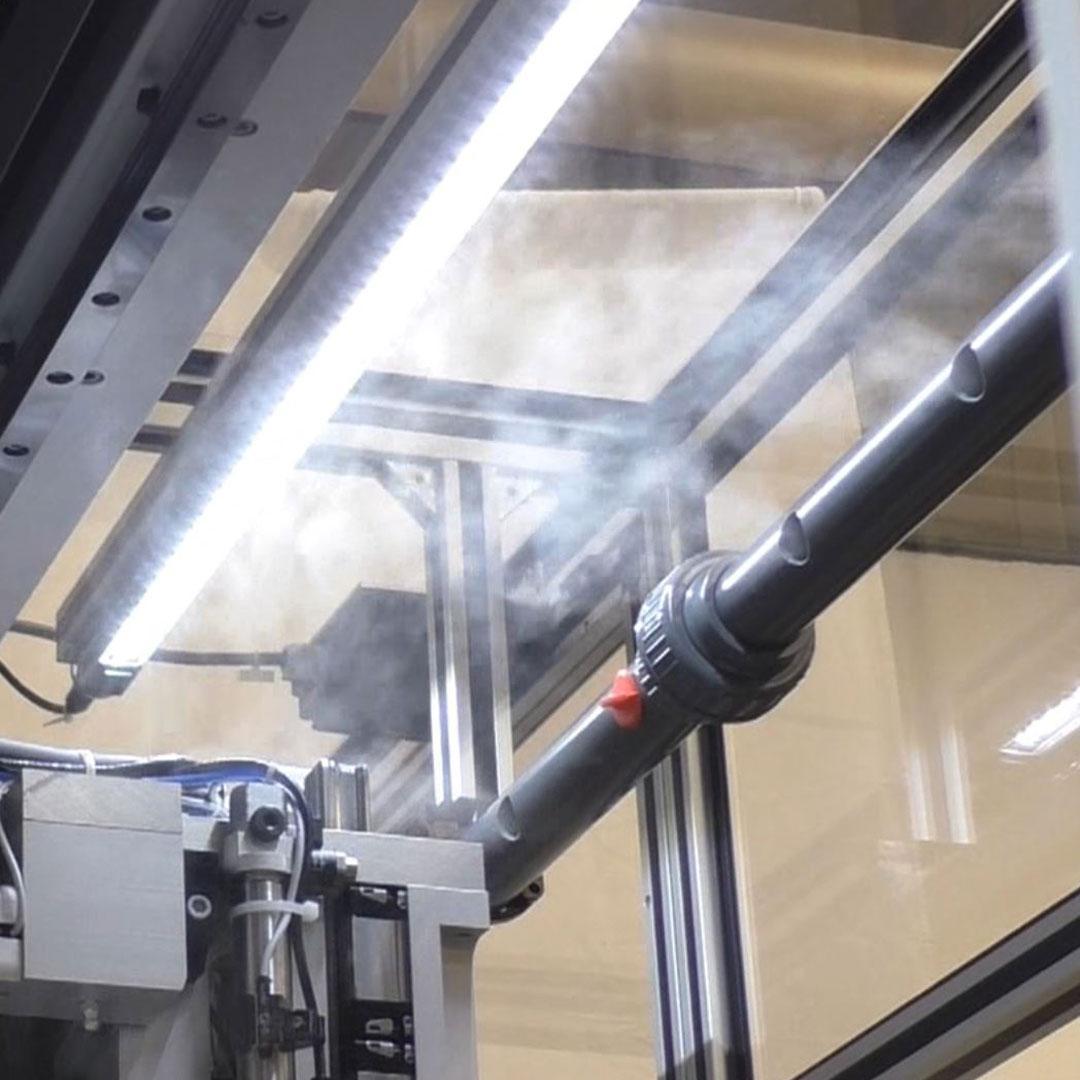

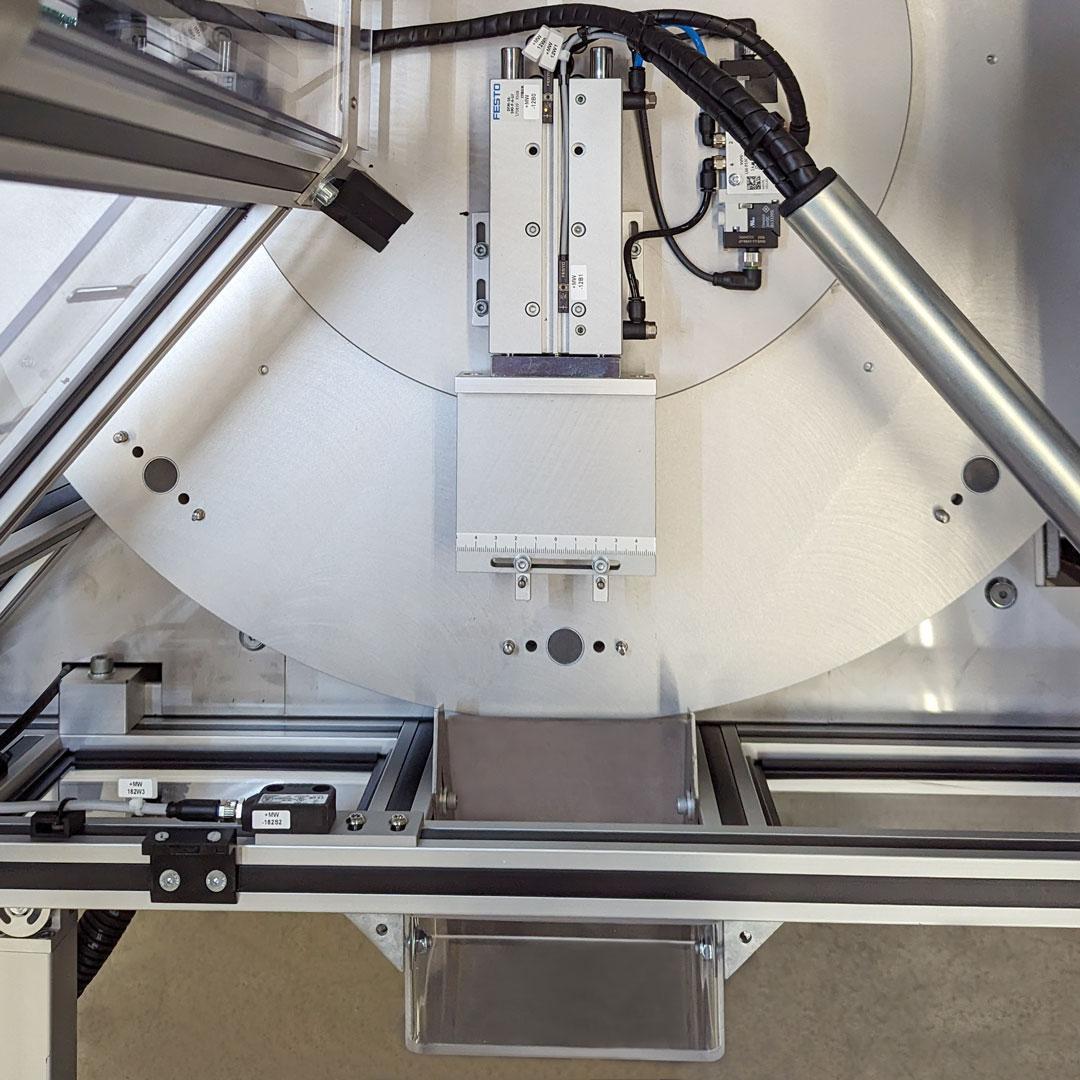

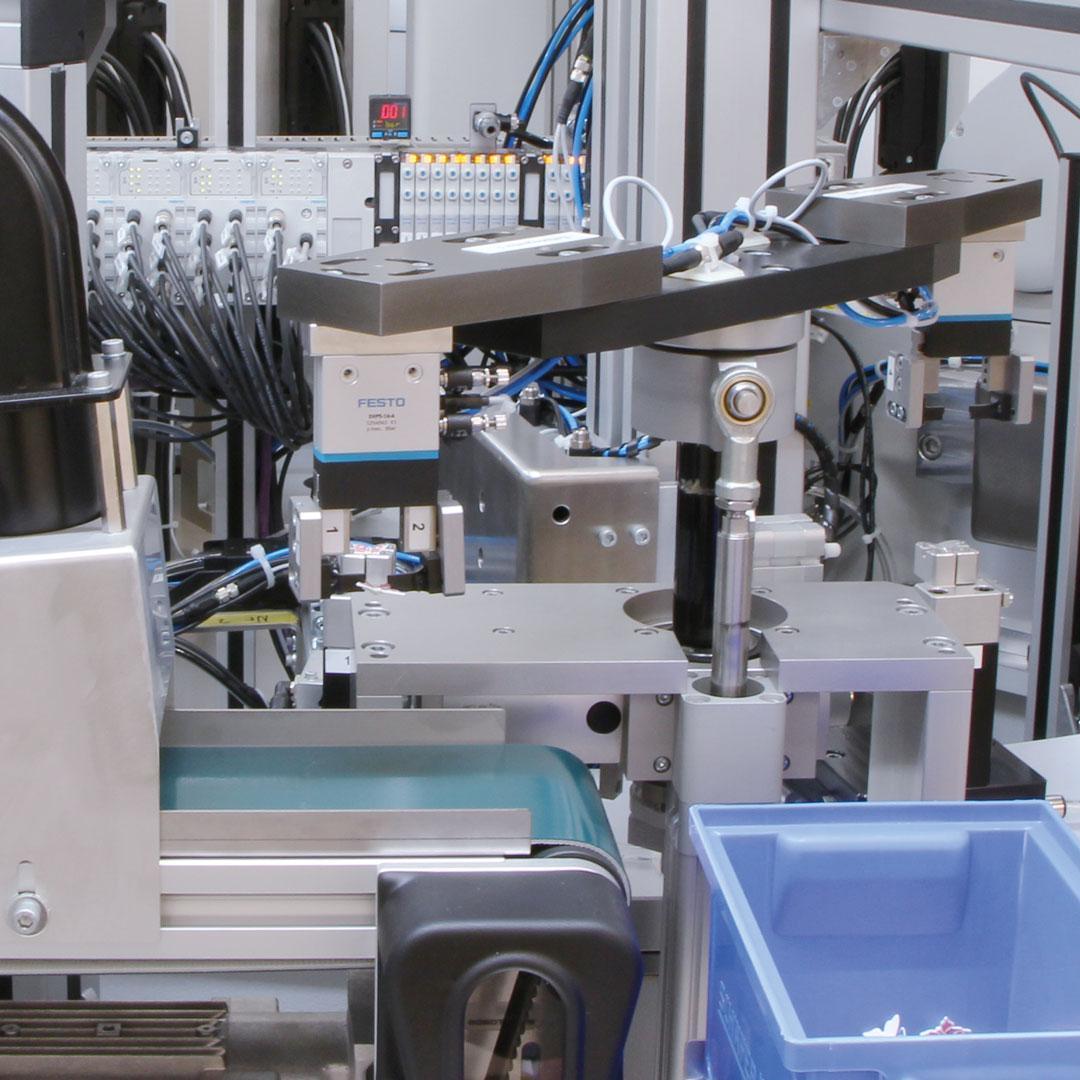

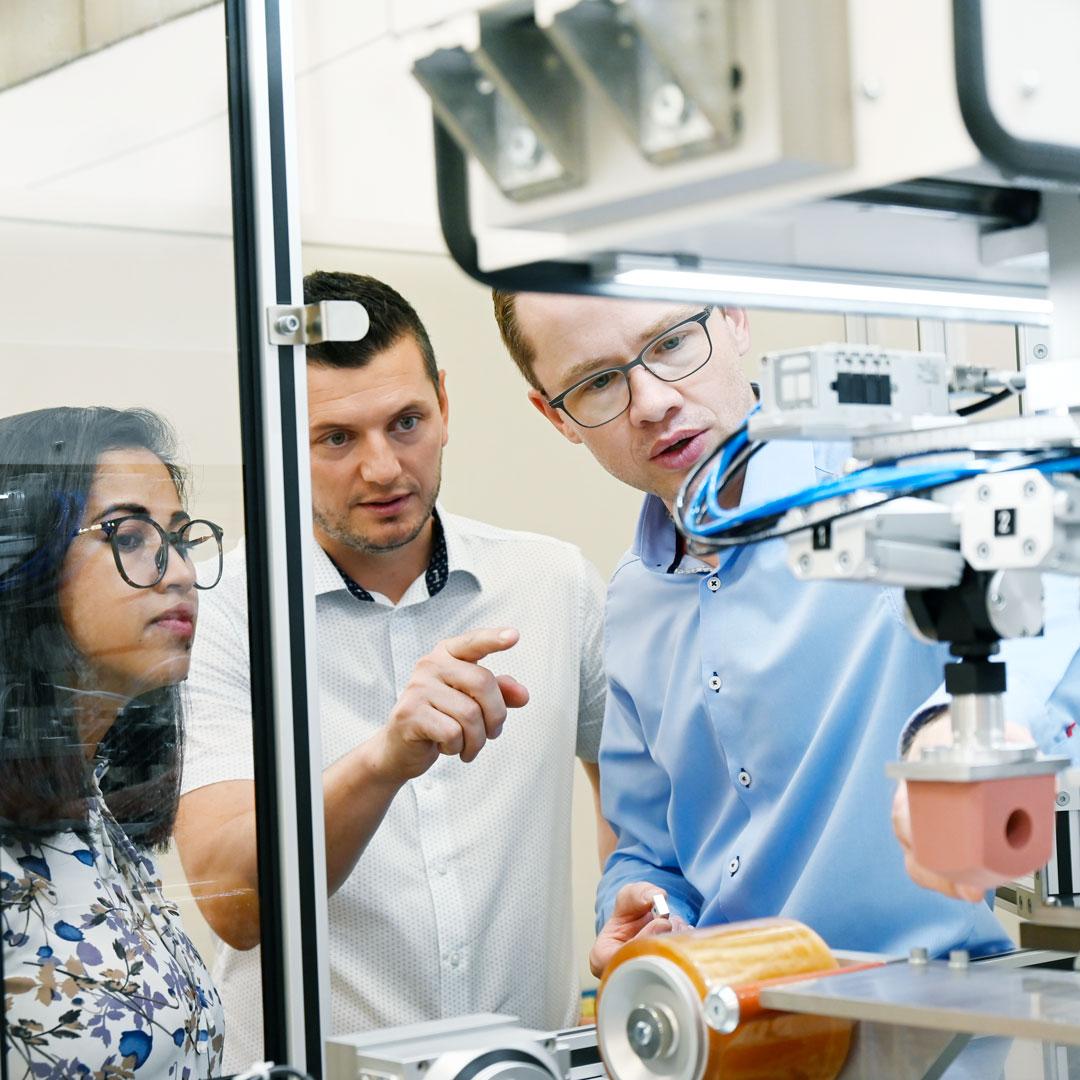

Pad printing is a traditional printing process, but at the same time offers an infinite variety of innovative possibilities for the most diverse applications. For over 50 years, we have played a decisive role in the development of pad printing. New technologies on the market are consistently implemented and integrated into our machines and systems. This means that today we can offer you not only the machines for pad printing themselves, but also complete and customised solutions for your application. On request with automatic feeding and unloading, vision systems, systems for achieving optimum ambient conditions and, of course, with innovative software options.