Pad printing inks and additives

The variety of available shades is enormous and offers the right solution for every requirement. All our colour series impress with their high brilliance and opacity.

At Teca-Print, we offer standard ink tones as well as mixed colours, with which special colours can be mixed according to the standard colour systems (e.g. RAL or Pantone). We also offer metallic effect colours, fluorescent colours and colours with special effects. The 4C process colours (CMYK) are available for “photo prints”.

A suitable ink type for every substrate

Our range of ink series is as varied as the different materials.

To ensure that your print not only looks good, but also achieves optimum adhesion, our range of different ink types is constantly growing. New materials and applications are constantly conquering the market. Accordingly, we are also developing our ink series together with renowned ink manufacturers, improving them or adding a new ink type to the range. We would be happy to provide you with comprehensive advice and carry out ink tests with various ink types for you.

Ink properties: 1- or 2-component inks, solvent-based or UV LED inks

Our pad printing inks are available with different properties.

Pad printing inks are generally solvent-based. Depending on the type of material to be printed, either 1-component or 2-component ink series are used. 1-component inks dry purely physically by evaporation of the solvent, while 2-component inks also have a chemical reaction that cross-links the ink film with the substrate. Some ink series can be applied in both 1- and 2-component versions.

Alternatively, LED UV pad printing inks are available. The solvent content of these inks is lower than that of conventional pad printing inks. LED drying is required to match the print object and ink.

Additives

Additives are used to adjust the pad printing inks ready for printing and for specific applications.

Additives play a key role in pad printing, because in addition to the basic function of ensuring the correct viscosity or adding hardener for a 2-component application, other ink properties can also be influenced.

The wide variety of additives available makes it possible to adjust the ink to different processing parameters or special application requirements, such as indoor or outdoor use or other environmental influences.

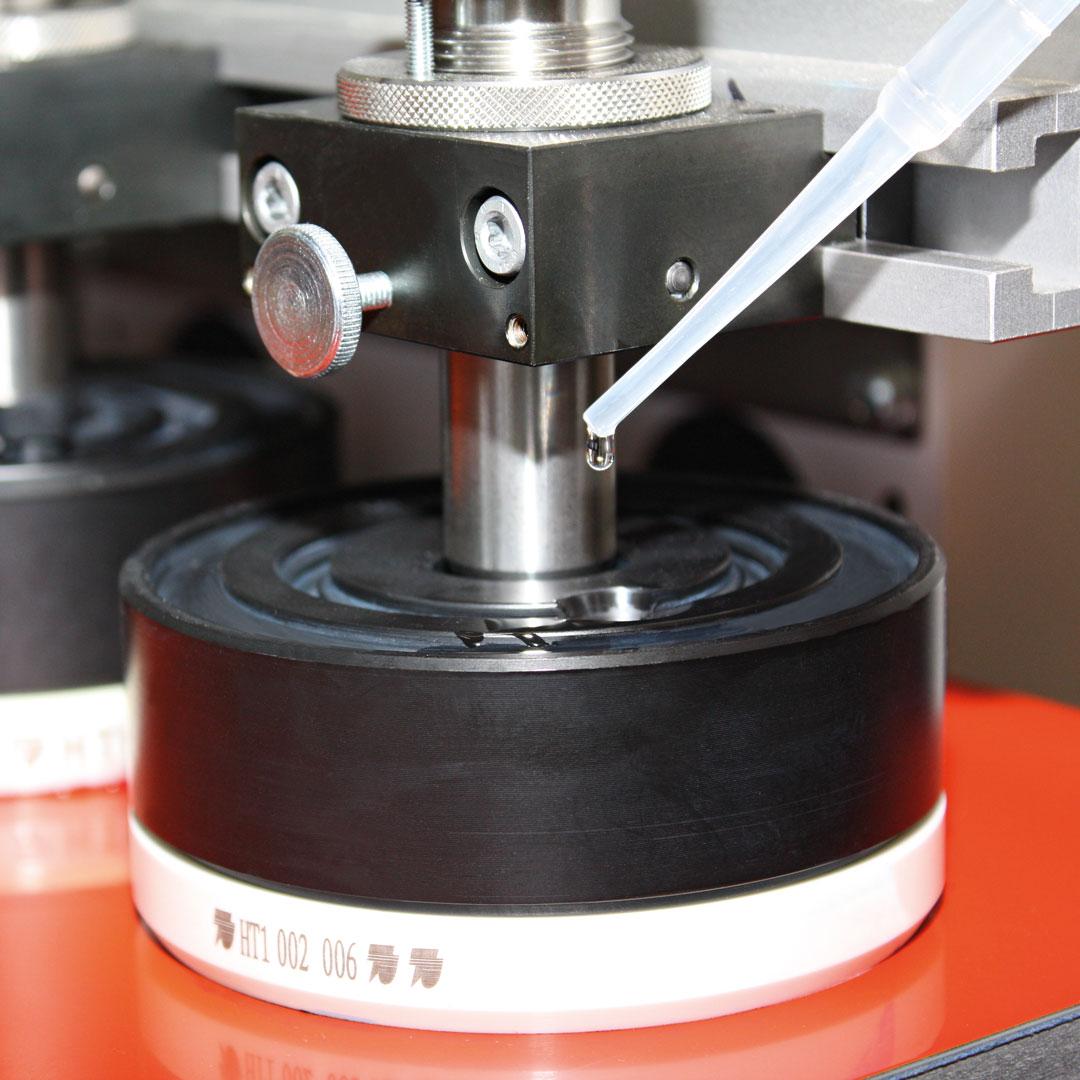

Alternative applications

Pad printing is ideal for transferring various other media, such as adhesives, greases, pastes or varnishes.

One important area, for example, is “printed electronics”. The conductive pastes can also be printed directly onto uneven, three-dimensional surfaces. Pad printing therefore offers possibilities that no other printing process can match.

Pad printing impresses with brilliant, highly opaque colours.

Teca-Print pad printing inks are usually supplied in one litre or one kg tins. The practical Teca-Print ink tubes of 200 ml or 200 g are also available for many ink series and colour shades.

Special colours, which are mixed especially for you, are usually already available in small quantities of 500 ml or 500 g.

Teca-Print pad printing inks are ready for printing at the time of delivery, but must be stirred thoroughly and then adjusted to the desired viscosity. For 2-component inks, the hardener must be mixed in well before the thinner is added.

Please contact us using the contact form, by e-mail or phone. We will be happy to send you further information or give you personal assistance.