TPX 250

Your advantage:

- 1 to 4 colours

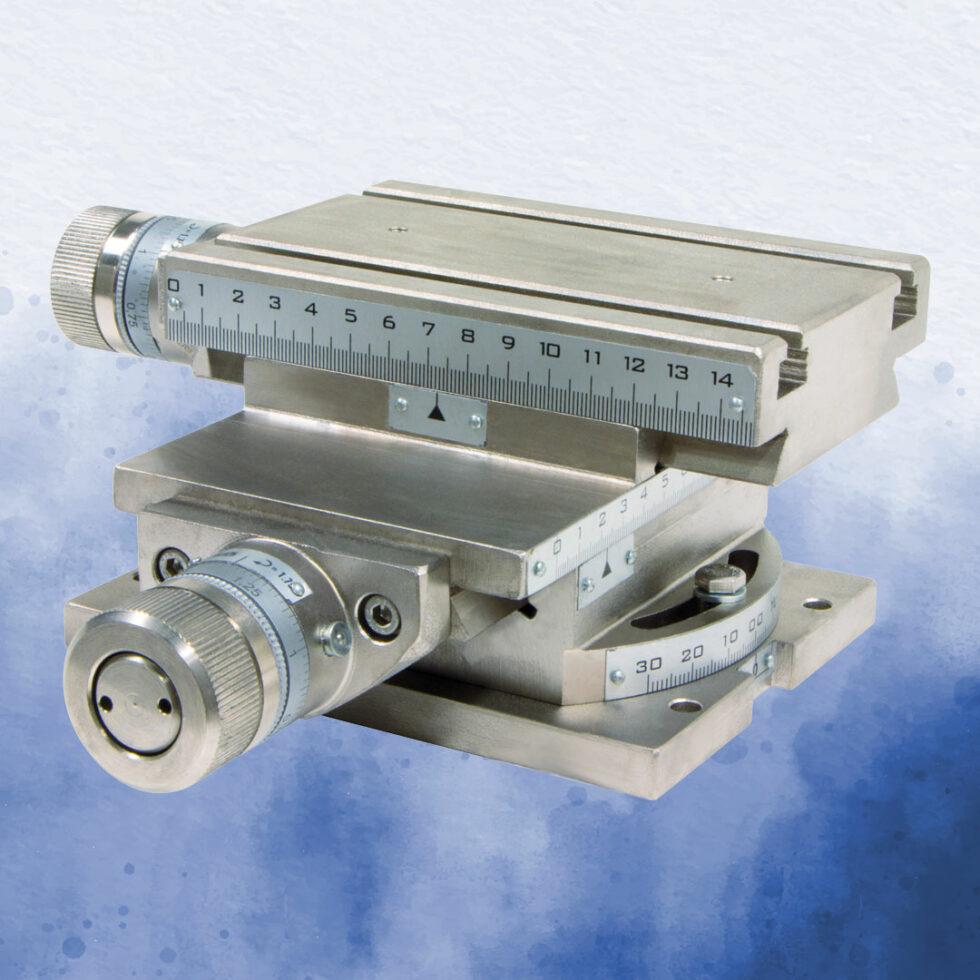

- highest precision and repeat accuracy

- electropneumatical

- compact design

- open inking system

- wide range of peripherals available

The TPX 250 pad printing machine with an open inking system is driven electropneumatically. The compact printing machine shows its advantages especially at manual workstations.

The colour touch-screen enables a clear, user-friendly operation.

Highest print accuracy and repeatability characterize the TPX 250 as a universally suitable pad printing machine for a variety of applications.

The TPX 250 can be combined with many peripheral devices, e.g. the automatic thinner injection, with rotary or swing table, pad sliding device, etc. Various accessories such as machine bases or coordinate tables are of course also available.

The TPX 250 pad printing machine impresses with its compact design and maximum precision, even for demanding print applications.

Motivated, focussed and enjoying their work: our team during assembly

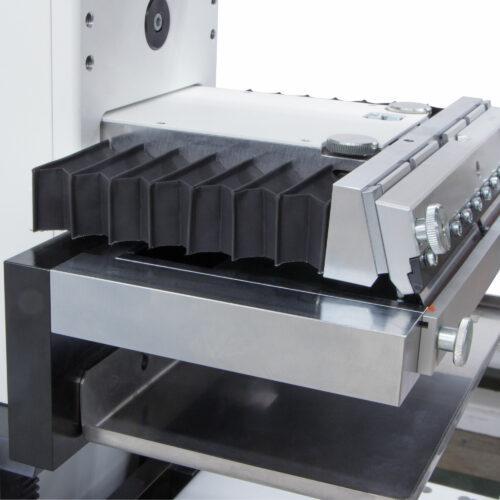

The pad sliding device makes 2-colour printing easy and reliable.

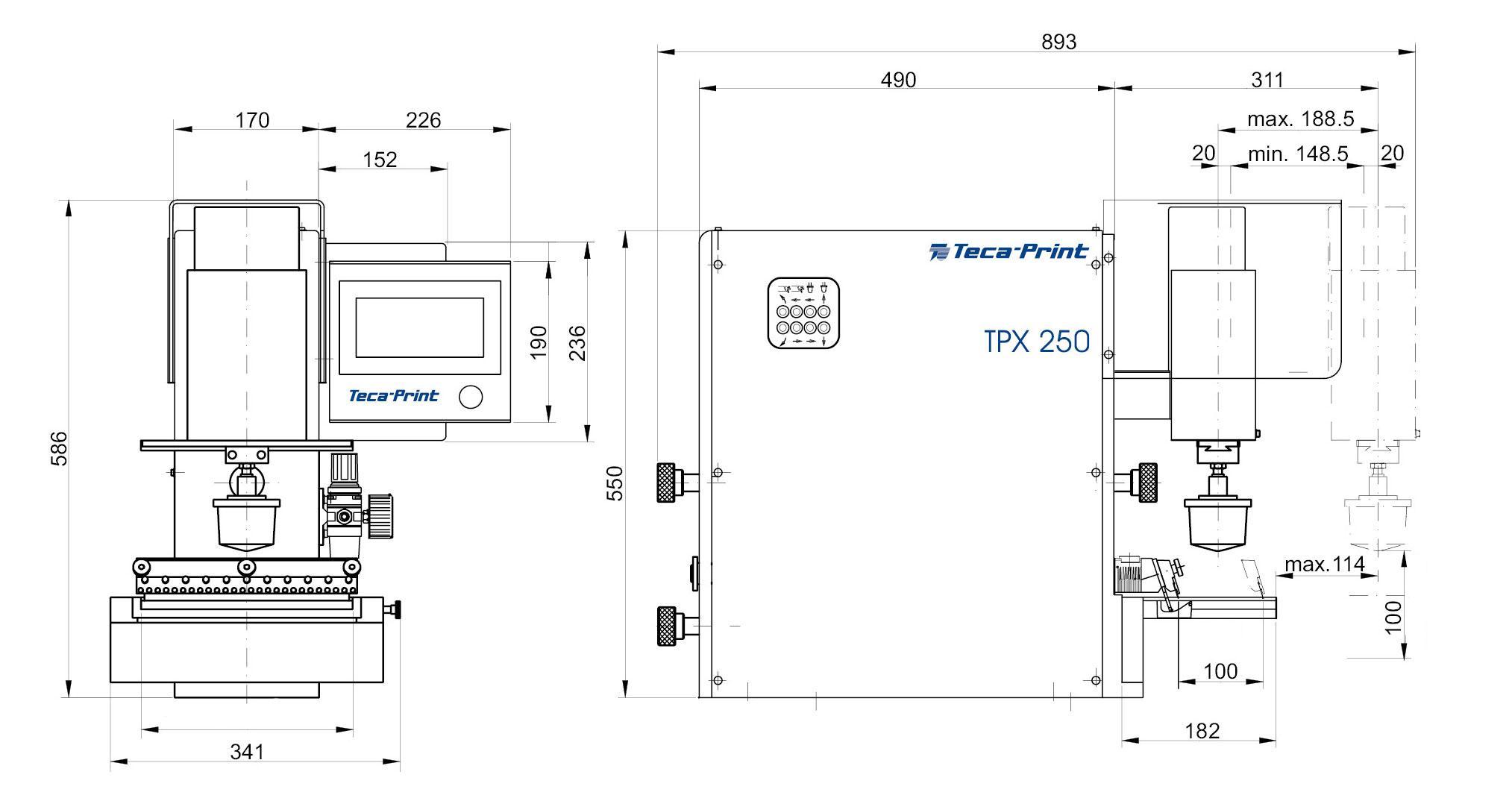

Technical data TPX 250

Number of colours:

up to 4 colours

Plate sizes:

standard plate widths: 80 / 100 / 120 / 130 / 250 mm

standard plate depths: 80 / 100 / 120 mm

Output:

up to 1’400 cycles per hour

Drive system:

electropneumatical

Repeat accuracy:

< ± 0.02

Printing force:

700 N (printing force has to be balanced)

Mains connection:

230 V / 50 Hz, 5 – 6 bar air pressure

Air consumption:

0.85 litres / cycle at 6 bar

Control:

PLC – HMI touchscreen

Tamponvertikalhub:

100 mm, elektrisch stufenlos verstellbar

Outreach pad carriage:

114 mm

Weight:

approx. 70 kg without machine base

Dimensions (WxHxD):

471 x 586 x 893 mm

Many customers appreciate the medium size of our TPX 250 – compact, precise and reliable.

Request a TPX 250 brochure (pdf):